Shopping cart

Your cart empty!

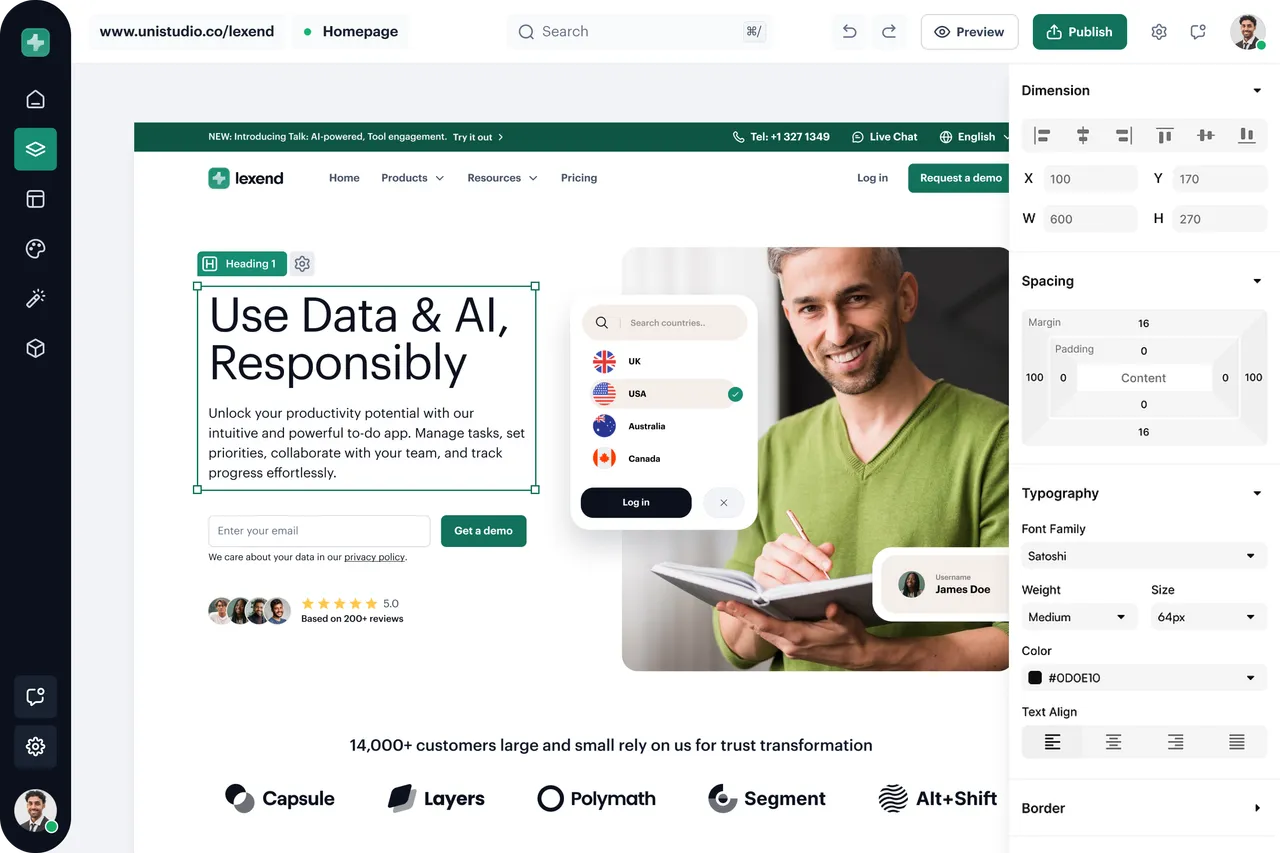

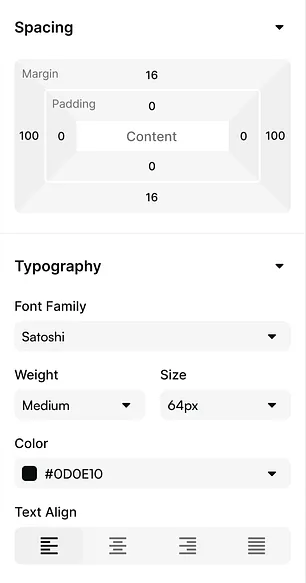

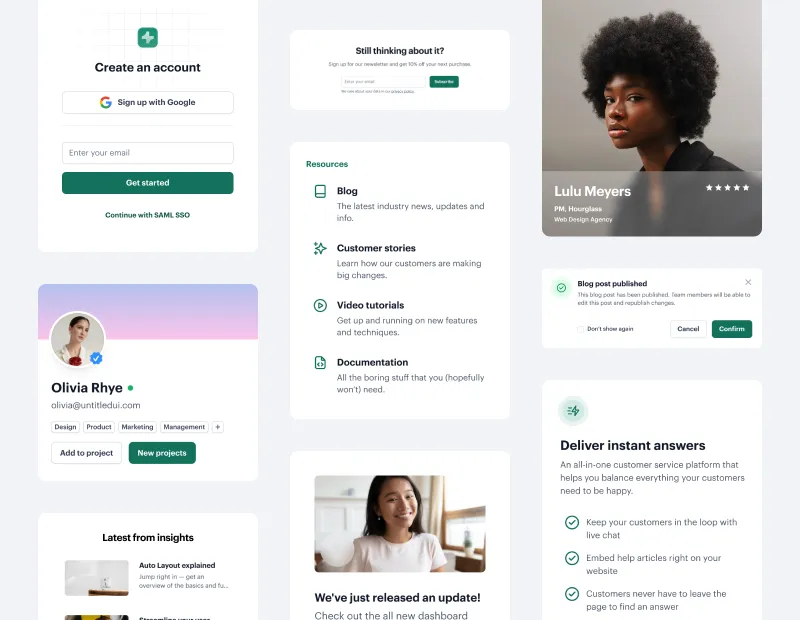

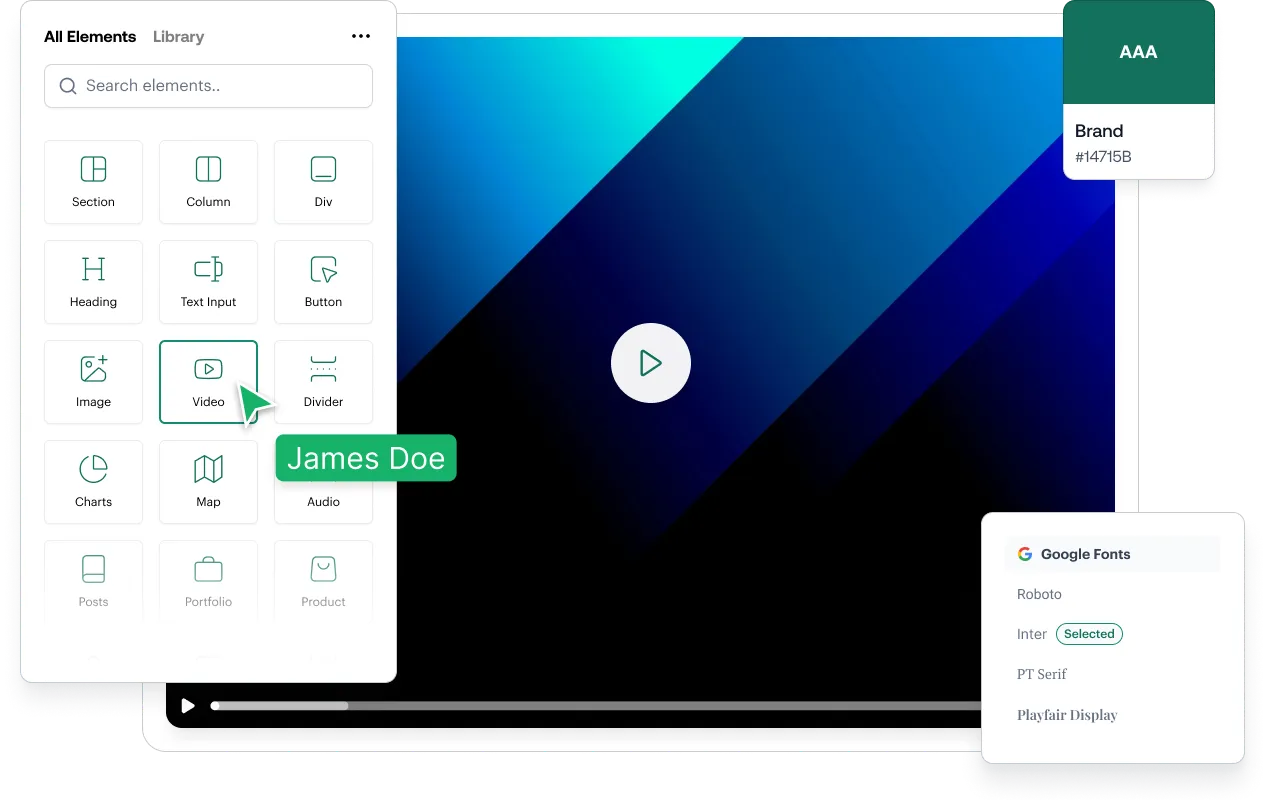

Easy-to-use and powerful page builder, your gateway to intuitive tools and expansive customization options that transform how you build websites.

Get startedNo credit cards required - 14 days free trial.

Unleash your creativity with our builder's powerful features and intuitive interface, experience the difference.

Intuitive interface Drag-and-Drop for building pages by dragging and dropping elements.

Try it now

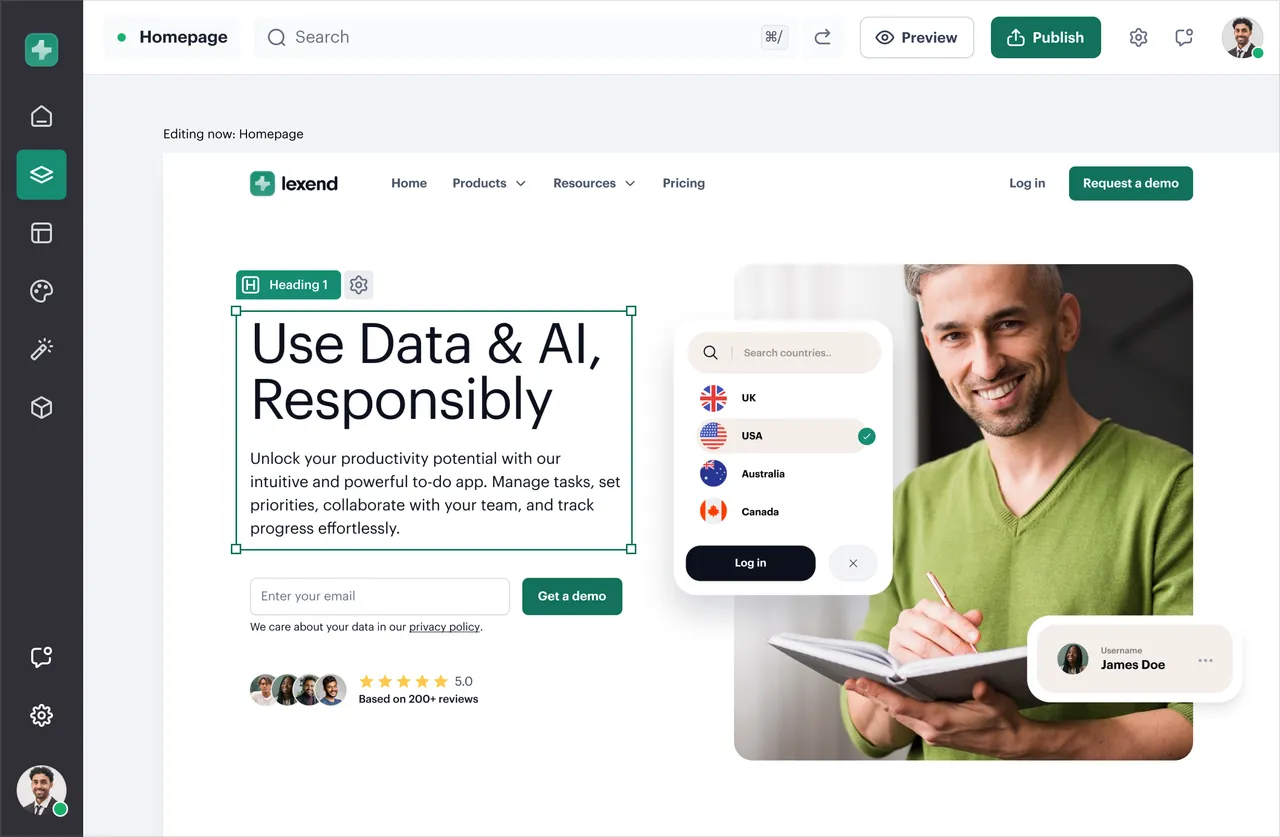

Unlock your productivity potential with our intuitive and powerful Dashboard UI Components.

Easy-to-use and powerful page builder, your gateway to intuitive tools and expansive customization options that transform how you build websites.

Unleash your creativity with our builder's intuitive UI Components, experience the difference.

Easy-to-use and powerful page builder, your gateway tointuitive tools andexpansive customization options that transform how youbuild websites.

No extra charges. No hidden fees.

Build a hobby site with every basic features.

Get startedFree Forever!

Build unlimited websites with every pro feature

Get startedBilled annually.

Prices exclude any applicable taxes.

Don't just take our words for it!

We’re looking for people who share our vision! most of our time used to be taken up by most of who created new websites for thier businesses.

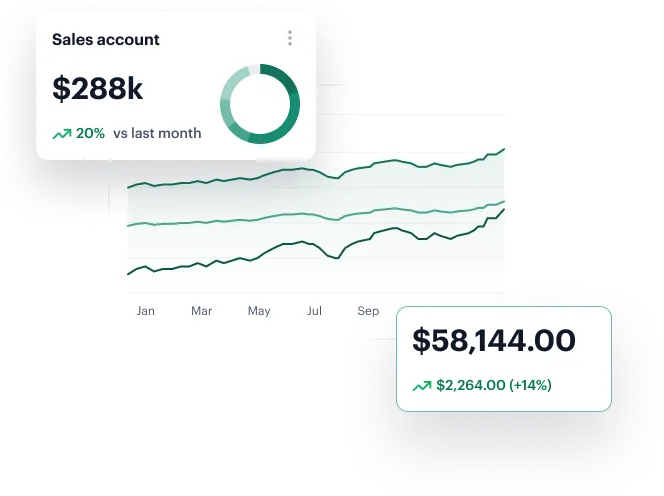

Still have a question?The equipment downtime is usually reduced with the help of predictive analysis. It helps the industrialists to anticipate the accurate asset performance and health, thus scheduling on-time machine checks.

Factory downtime mainly occurs when the equipment starts performing low of their potential. It further affects the overall production as the maintenance and rectifying other issues takes time. This delays the production and hence affects the overall demand fulfillment.

IoT technology is well-equipped with advanced algorithms and analytics tools, which provide the managers with detailed insights regarding machine’s performance and its health. It helps identify the machine downtime accurately.

Broadly there are three types of machine downtimes: Shutdown or outage downtime, Schedule or planned downtime, Unscheduled or unplanned downtime.

Yes. Our system is built to retrofit with your current PLC-based machines and legacy infrastructure. Whether you have older equipment or a modern setup, we can connect and digitize it.

Simply reach out via our Schedule a Demo form. Our experts will assess your machines, communication systems, and factory layout to create a tailored implementation plan for your specific goals.

Our solution workswith a wide range of machines-CNCs,PLCs,injection molding,packaging,compressors,and more.If it runs in your factory, we can likely monitor it.

Absolutely. Our solution is fully customizable. We support multi-location, multi-factory environments and can tailor dashboards, alerts, KPIs, and workflows based on your industry or process needs.

Our philosophy is simple — hire a team of diverse, passionate people and foster a culture that empowers you to do your best work.

Join the thousands of satisfied users and take your business to the next level today and the power of streamlined business operations.

The Industrial Internet of Things (IIoT) is revolutionizing manufacturing by enabling real-time monitoring, predictive maintenance, and smart automation. It helps reduce downtime, optimize resources, and ensure consistent product quality, leading to safer, more efficient, and cost-effective operations.

Explore Industries