Shopping cart

Your cart empty!

Industrial manufacturers today face complex challenges that affect productivity, quality, and profitability. At IIoT Technologies, we bridge these gaps with intelligent, data-driven solutions tailored for PLC-based machine environments.

Problem: Frequent, unpredictable machine stoppages lead to production losses, missed deadlines, and high maintenance costs.

Our Solution:

• Real-time Downtime Monitoring with root cause categorization.

• Downtime Pareto Analysis with integrated maintenance codes.

• MTBF & MTTR tracking for reliability insights.

✅ Result: Reduced unplanned downtime and optimized maintenance schedules.

Problem: Plants struggle with low utilization rates and can't pinpoint whether performance issues stem from availability, performance, or quality.

Our Solution:

• Real-time OEE Monitoring with drill-downs.

• Cycle Time Variance Analysis to detect bottlenecks.

• Workforce Efficiency Tracking to improve human performance.

✅ Result: Better resource utilization and higher throughput.

Problem: Quality issues lead to customer dissatisfaction, rework, and scrap generation.

Our Solution:

• Rejection & Rework Analysis by product, machine, and shift.

• PPM (Parts Per Million) Reporting and cost of quality.

• QA-QC Integration for in-line and final inspection tracking.

✅ Result: Reduced quality failures and increased customer trust.

Problem: Relying on logbooks and Excel leads to inaccuracies and delayed decisions.

Our Solution:

• Automated Production Counters with good/bad part tracking.

• Interactive Dashboards for real-time visualization.

• Production History Reports for audit, analysis, and compliance.

✅ Result: Digitized shop floor with real-time control.

Problem: No visibility into how raw materials, machines, and human inputs impact the final output.

Our Solution:

• End-to-End Traceability from raw materials to delivery.

• Sensor Integration (temperature, pressure, tonnage, etc.) for granular control.

• Audit Trails for all quality and production events.

✅ Result: Full process transparency for audits and root cause analysis.

Problem: Machines consuming excess energy go unnoticed, leading to high operational costs.

Our Solution:

• Energy Monitoring Dashboards per machine/shift/product.

• Carbon Footprint Tracking for environmental compliance.

• Anomaly Alerts for spikes in usage.

✅ Result: Reduced energy bills and improved sustainability.

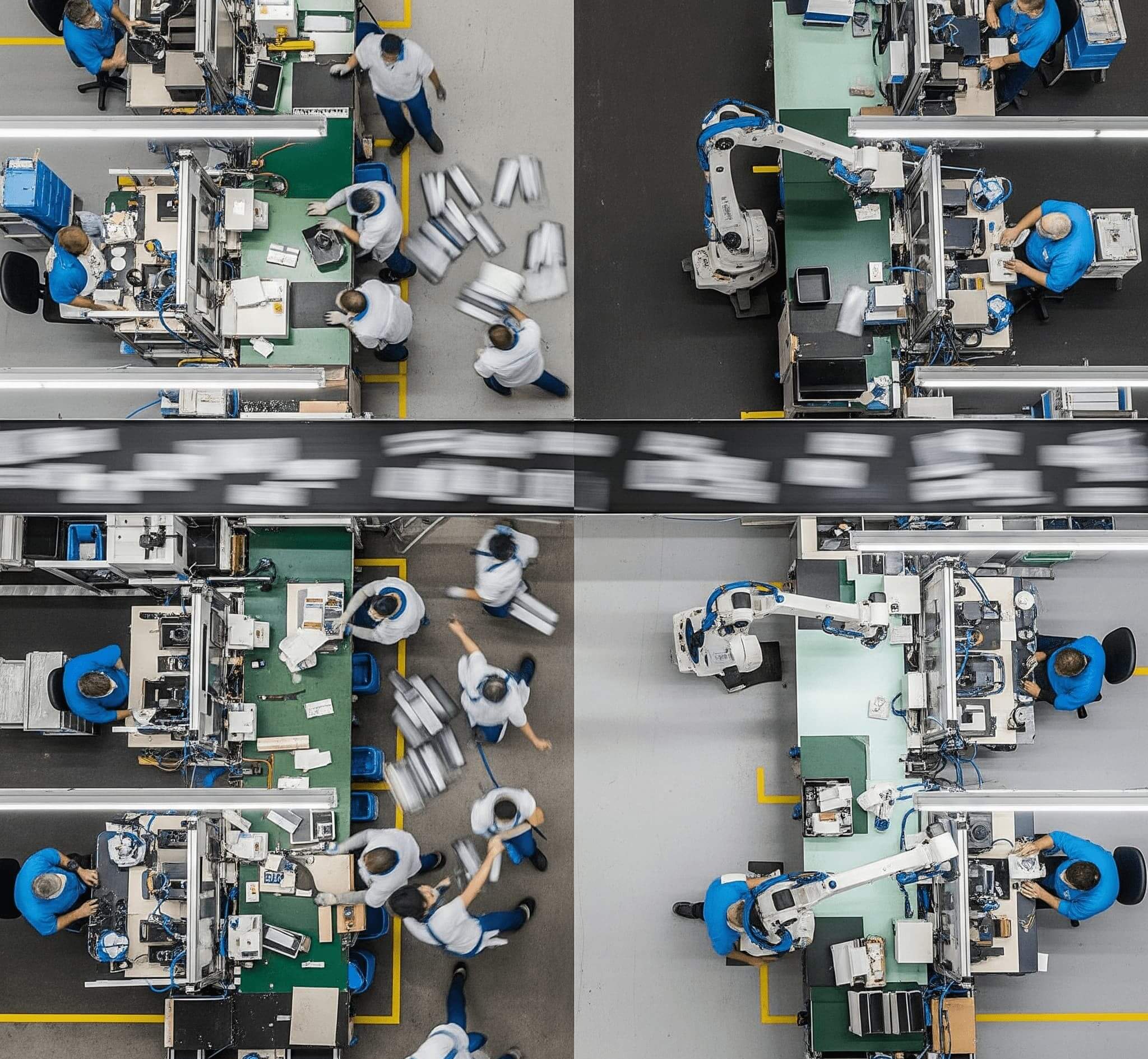

Problem: Some operators and machines are overloaded while others stay idle.

Our Solution:

• Dynamic Workload Balancing based on real-time data.

• Line Balancing Metrics to improve flow.

• Operator Efficiency Reports to manage teams better.

✅ Result: Streamlined operations and reduced inefficiencies.

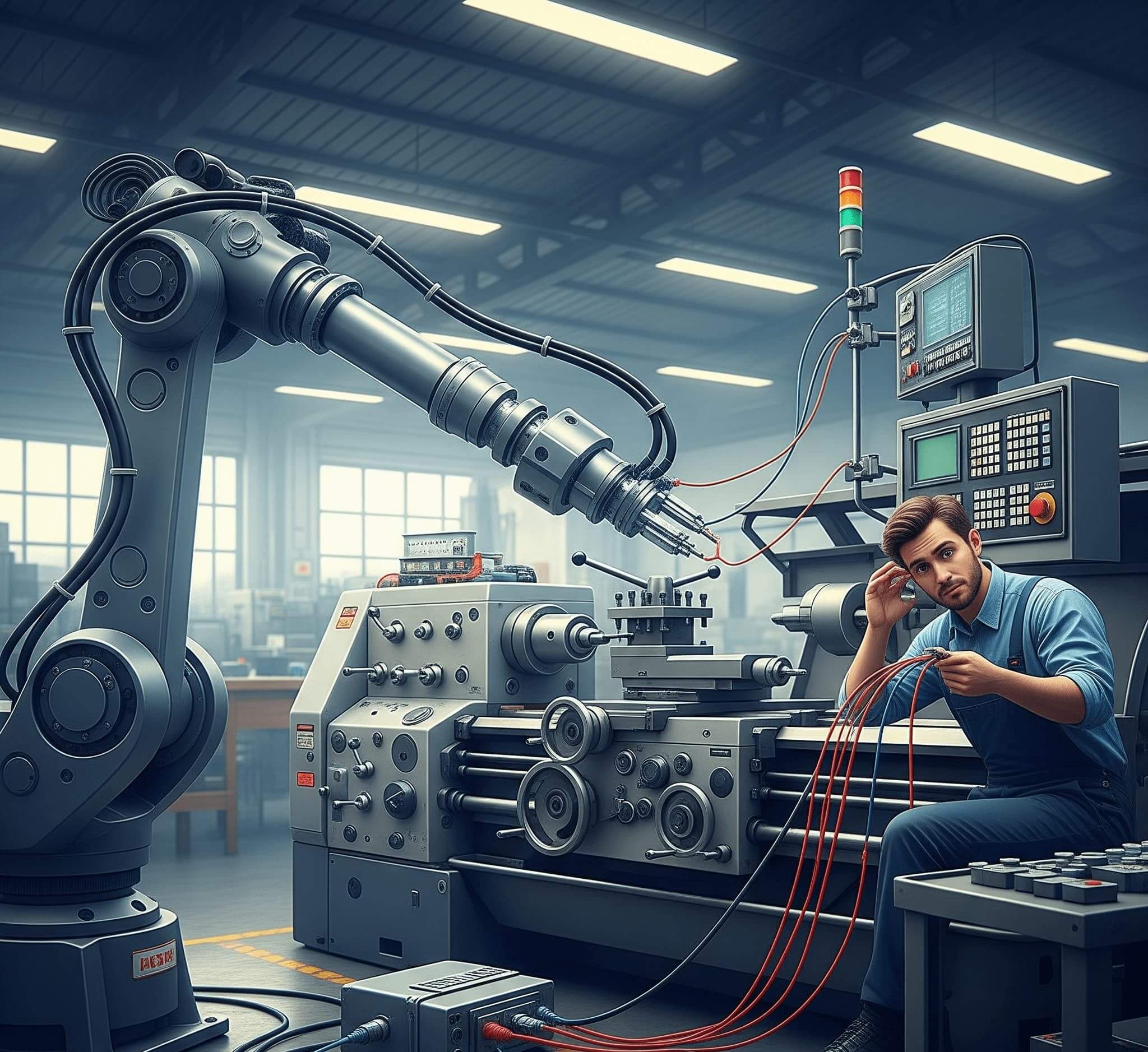

Problem: Difficulty in connecting machines, ERP, and legacy systems.

Our Solution:

• ERP & SAP Compatibility (push & pull APIs).

• Universal PLC Support for easy integration.

• Modular Architecture for scalable, custom deployments.

✅ Result: Seamless digital transformation without infrastructure overhaul.

IIoT Technologies is built to eliminate guesswork, reduce waste, and unlock operational excellence. Whether you're a small unit or a multi-plant enterprise, we tailor solutions to your needs.

Book a free consultation 👉