Shopping cart

Your cart empty!

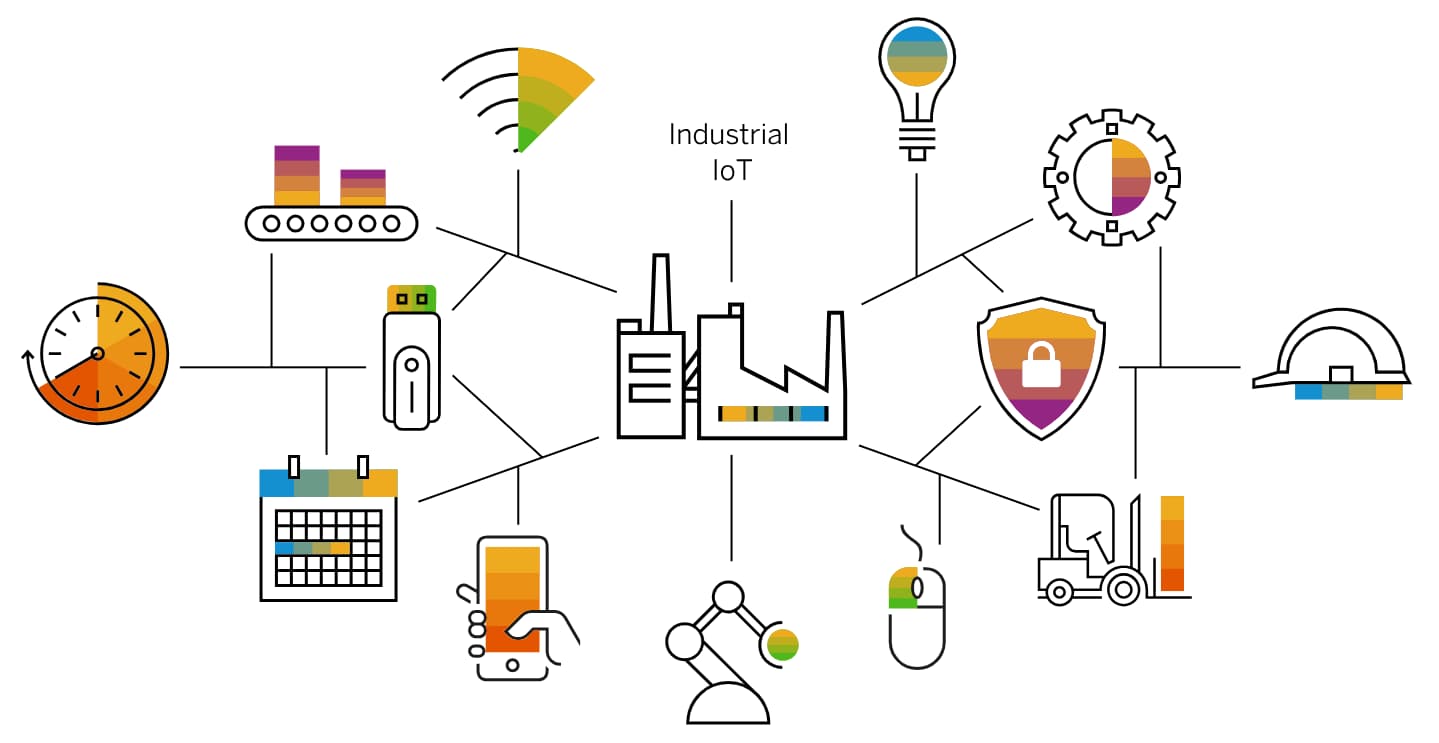

IIoT extends IoT into industrial environments, driving efficiency, automation, and intelligent operations.

The Industrial Internet of Things (IIoT) connects machines, equipment, and processes using sensors, software, and data analytics to optimize industrial operations. Unlike consumer-focused IoT, IIoT is built for harsh industrial environments, enabling automation, predictive maintenance, and smarter decision-making.

IIoT uses sensors and fast connectivity to collect real-time data from machines.

The data is analyzed in the cloud or at the edge to identify patterns, detect issues, and enable predictive maintenance.

Live data helps manufacturers monitor operations, improve efficiency, and reduce downtime.

IIoT connects traditional manufacturing with digital tech, enabling the shift to smart factories.

Reduce inefficiencies by enabling real-time monitoring and automated process optimization.

Enhance product quality through data-driven insights and precise process control enabled by IIoT.

Use sensor data to predict machine failures before they happen. Helps reduce unplanned downtime and maintenance costs.

Track equipment status, production progress, and performance in real-time across the factory floor.

Automatically calculate OEE based on Availability, Performance, and Quality metrics to evaluate and improve machine productivity.

Monitor the location and usage of machines, tools, and materials to maximize resource utilization.

Track energy consumption per machine or process to reduce waste and improve sustainability

Use IoT sensors and barcode/vision systems to ensure products meet quality standards in real time.

Integrate material movement with real-time data to reduce stockouts, delays, and excess inventory.

Access machine performance and alerts remotely from any location via cloud-based dashboards.

Monitor temperature, humidity, pressure, and air quality to ensure compliance and safe working conditions.