Shopping cart

Your cart empty!

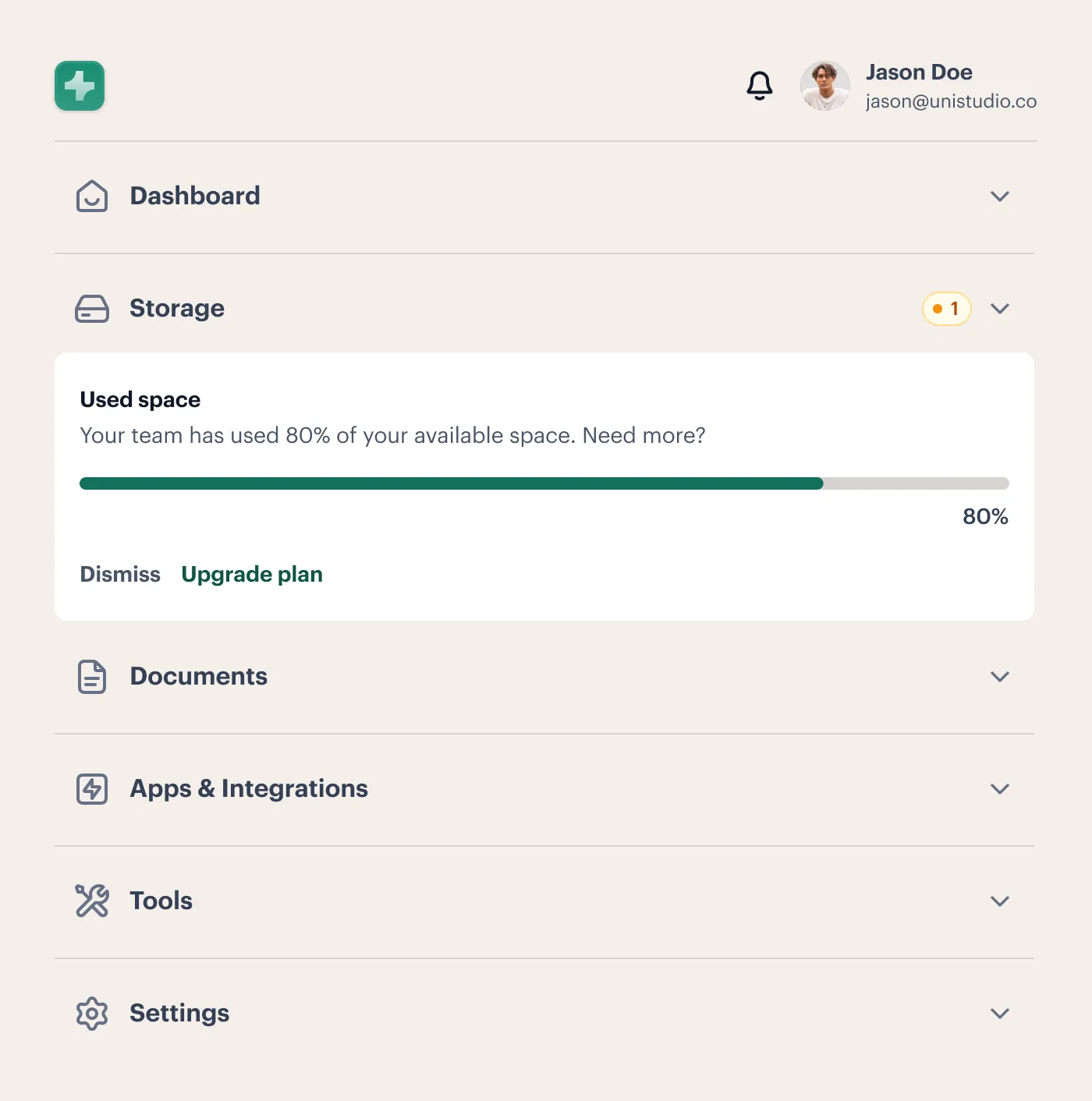

Say goodbye to the hassle of managing multiple software and tools for different tasks. Lexend offers a comprehensive suite of tools that cover all aspects of your business.

We care about your data in ourprivacy policy.

Lexend is designed to make your work life easier and more efficient.

Track of leads

Satisfied users

Team collaborations

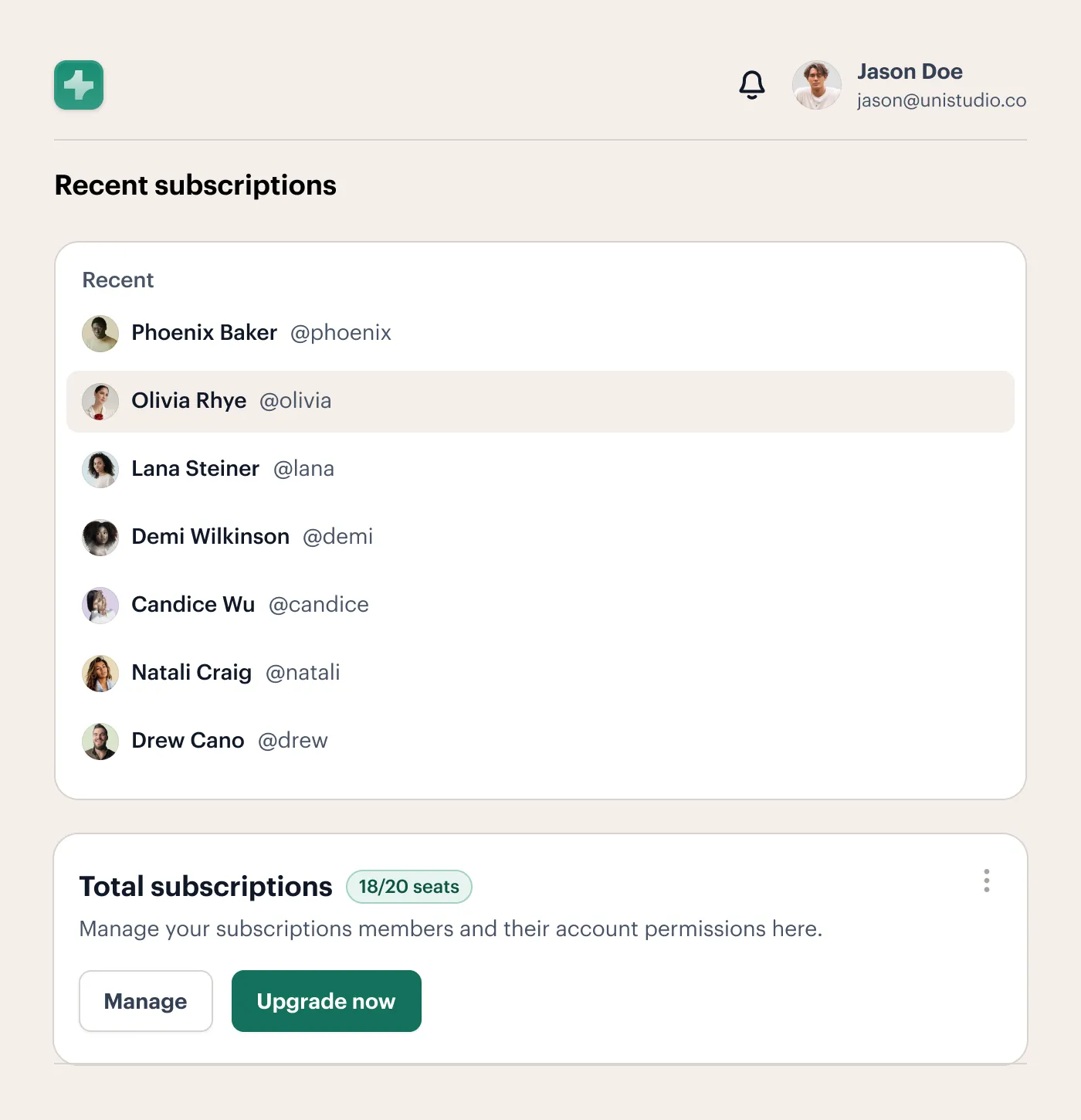

Join the thousands of satisfied users and take your business to the next level. Trusted by over 2,500 startups.

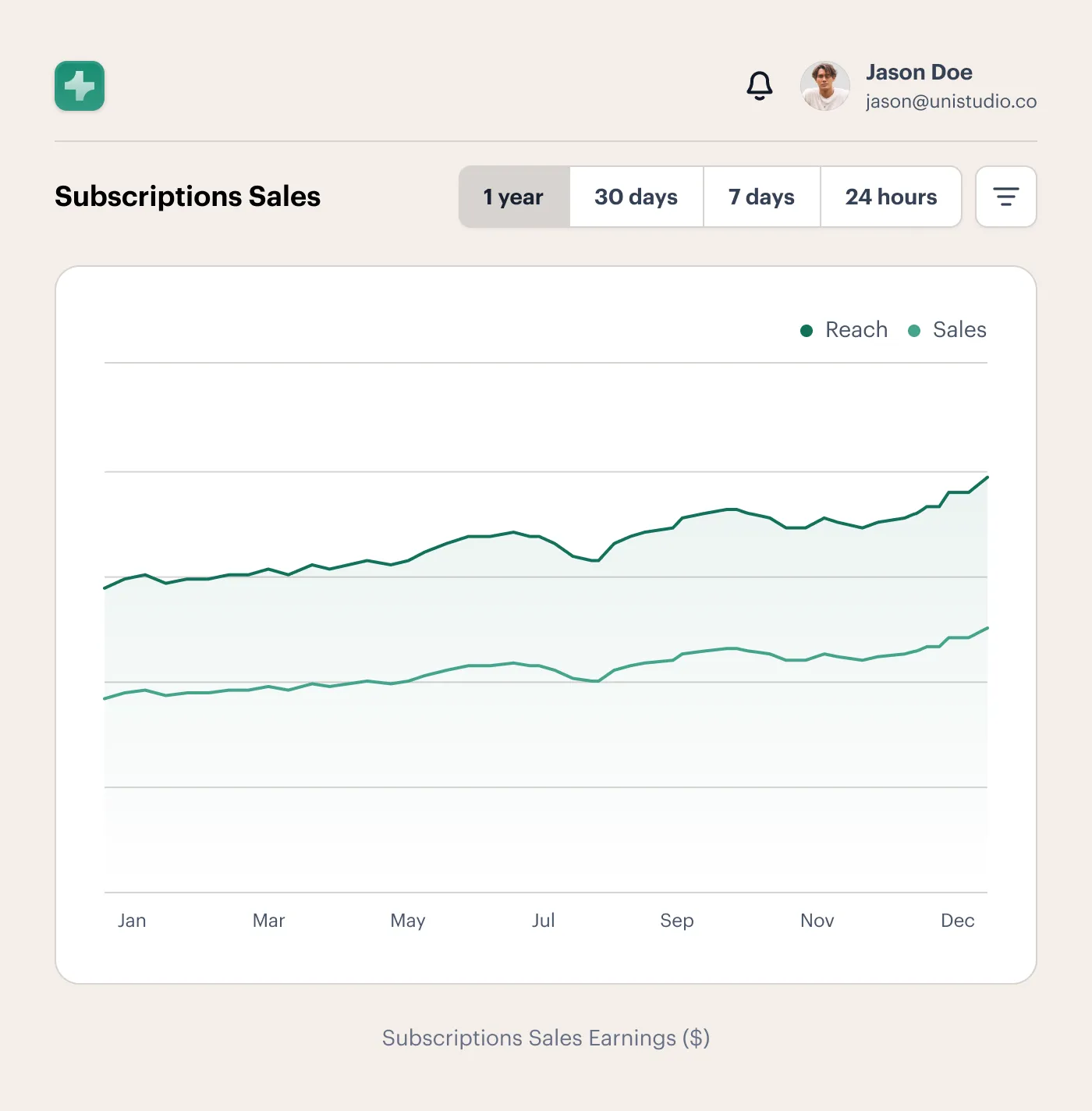

We offers advanced project management features such as Gantt charts, task dependencies, and resource allocation

Let's find out

An all-in-one customer service platform that helps you balance everything your customers need to be happy.

Let's find out

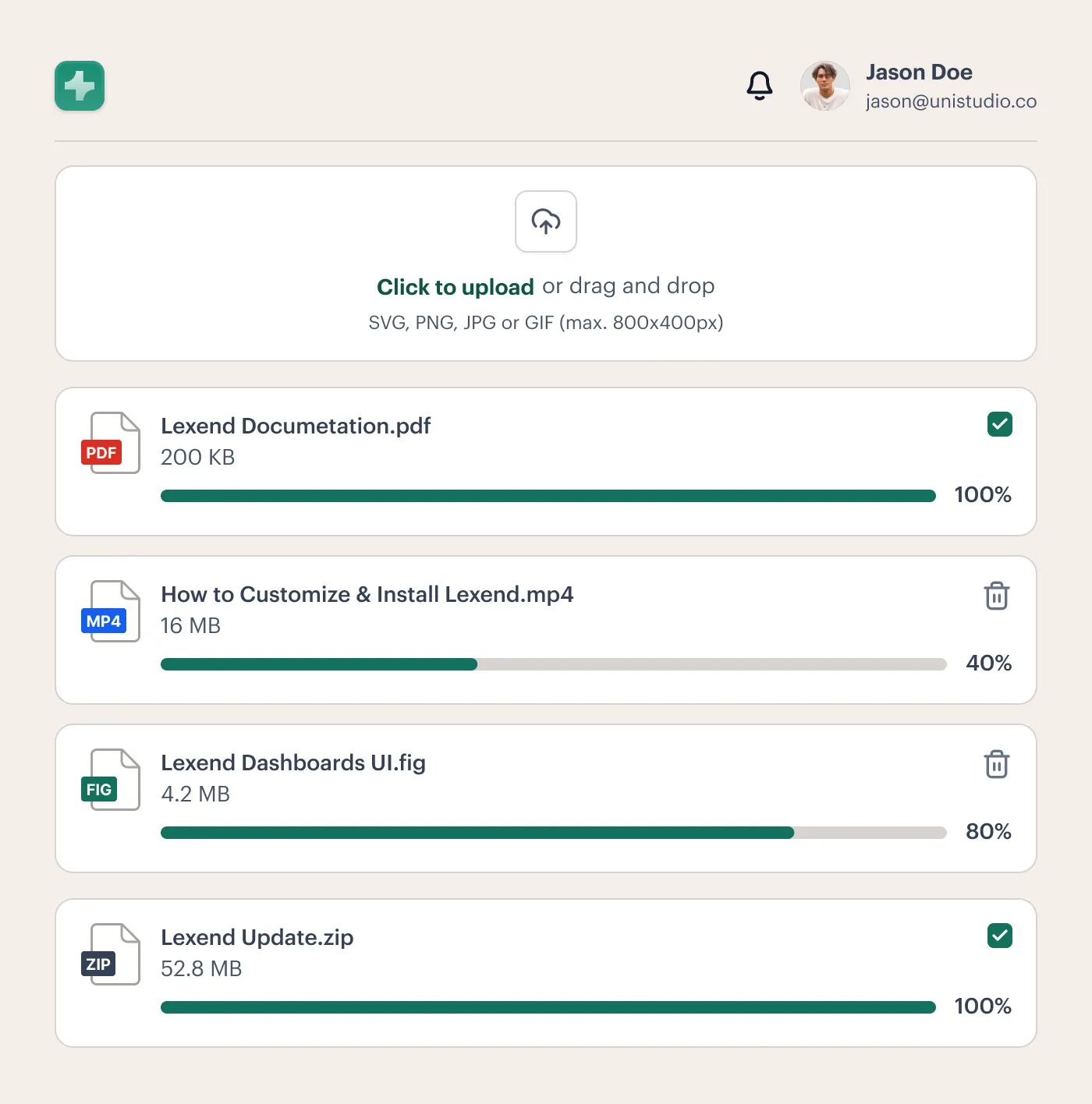

You can easily assign tasks, share files, and communicate with your team in real-time, no matter where they are located.

Let's find out

Get real-time access to approvals, comments and version tracking. Smart features like variables and conditional logic help you eliminate Tool errors.

Let's find outJoin over 2,500+ startups already growing with Lexend.

No extra charges. No hidden fees.

Billed annually.

Billed annually.

Billed annually.

Prices exclude any applicable taxes.

The equipment downtime is usually reduced with the help of predictive analysis. It helps the industrialists to anticipate the accurate asset performance and health, thus scheduling on-time machine checks.

Factory downtime mainly occurs when the equipment starts performing low of their potential. It further affects the overall production as the maintenance and rectifying other issues takes time. This delays the production and hence affects the overall demand fulfillment.

IoT technology is well-equipped with advanced algorithms and analytics tools, which provide the managers with detailed insights regarding machine’s performance and its health. It helps identify the machine downtime accurately.

Broadly there are three types of machine downtimes: Shutdown or outage downtime, Schedule or planned downtime, Unscheduled or unplanned downtime.

Yes. Our system is built to retrofit with your current PLC-based machines and legacy infrastructure. Whether you have older equipment or a modern setup, we can connect and digitize it.

Simply reach out via our Schedule a Demo form. Our experts will assess your machines, communication systems, and factory layout to create a tailored implementation plan for your specific goals.

Our solution workswith a wide range of machines-CNCs,PLCs,injection molding,packaging,compressors,and more.If it runs in your factory, we can likely monitor it.

Absolutely. Our solution is fully customizable. We support multi-location, multi-factory environments and can tailor dashboards, alerts, KPIs, and workflows based on your industry or process needs.

Our philosophy is simple — hire a team of diverse, passionate people and foster a culture that empowers you to do your best work.

Join the thousands of satisfied users and take your business to the next level today and the power of streamlined business operations.

Help you keep track of leads, contacts, and deals, making it easier to nurture and convert prospects into loyal customers.

You can personalize it to display the most relevant information and metrics for your business, giving you performance.

Start your 30-day free trial. Cancel anytime.

14-day trial, no credit card required.