In modern manufacturing, even a brief equipment failure or uneven workforce distribution can create costly delays and missed deadlines. Relying solely on reactive maintenance and manual workforce allocation is no longer efficient or sustainable. IIOT Technologies introduces an intelligent suite of tools that harness real-time data to predict machine issues before they occur and optimize operator productivity across shifts. This powerful combination ensures uninterrupted operations, improved asset longevity, and a more balanced and efficient workforce.

Waiting for machines to fail is a costly strategy. IIOT Technologies leverages sensor data and machine learning algorithms to detect early signs of wear, vibration, temperature spikes, or abnormal behavior. This predictive maintenance system alerts teams in advance, allowing scheduled interventions that minimize unplanned downtime and reduce maintenance costs. By replacing time-based servicing with condition-based maintenance, companies not only extend equipment lifespan but also avoid unnecessary production halts.

Tools are the backbone of manufacturing precision. Continuous monitoring of tool condition ensures that wear and tear don’t compromise quality. IIOT Technologies tracks tool usage, wear trends, and failure patterns in real time. Alerts are triggered as tools approach critical thresholds, enabling proactive maintenance or replacement. Additionally, the system correlates tool degradation with scrap generation, helping teams reduce material waste and optimize tool change schedules—resulting in higher efficiency and lower production costs.

IIOT Technologies also focuses on the human element. Real-time dashboards provide insights into operator workloads, productivity metrics, and skill utilization. By monitoring performance across shifts and workstations, managers can identify bottlenecks, redistribute tasks dynamically, and ensure fair workload distribution. This leads to better morale, fewer errors, and sustained productivity throughout the day. When people are empowered with the right data and support, both individual performance and overall operational efficiency rise.

Key Highlights:

🔄 Predictive Maintenance with MTBF & MTTR

IIOT Technologies leverages key performance metrics such as Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) to enhance predictive maintenance strategies. By analyzing historical failure patterns and repair durations, the system forecasts when a machine is likely to fail and estimates the time required for recovery. This enables maintenance teams to schedule interventions proactively—preventing unexpected breakdowns and minimizing downtime. The result is improved equipment reliability, optimized maintenance resources, and a smoother production flow that keeps operations running efficiently.

This data-driven approach allows maintenance teams to prioritize high-risk equipment and schedule repairs during planned downtimes rather than facing costly emergency interventions. It also helps in identifying bottlenecks in repair processes and opportunities to reduce repair time, further boosting overall equipment effectiveness (OEE). Ultimately, leveraging MTBF and MTTR within a predictive maintenance framework improves asset longevity, reduces unexpected breakdowns, cuts maintenance costs, and supports a continuous, efficient production workflow.

🔍 Sensor-Based Condition Monitoring

Real-time tracking of critical machine parameters such as temperature, pressure, vibration, and more provides invaluable insights into equipment health. Continuous monitoring of these signals enables early detection of anomalies that could indicate wear, misalignment, overheating, or other potential issues. By identifying deviations from normal operating conditions promptly, manufacturers can intervene before minor problems escalate into costly breakdowns. This proactive approach not only extends the lifespan of machinery but also improves safety and maintains consistent production quality.

Advanced sensor technologies, including accelerometers, thermal sensors, and pressure transducers, collect high-resolution data that is analyzed using machine learning algorithms and predictive analytics. These insights help identify subtle changes in machine behavior that human operators might miss, such as slight increases in vibration frequency or gradual temperature rise. Integrating sensor data with historical maintenance records and operational logs allows for a comprehensive understanding of equipment performance trends over time.

Additionally, real-time condition monitoring facilitates remote diagnostics and centralized control, enabling maintenance teams to respond quickly to alerts regardless of their location. This capability is especially beneficial for facilities with multiple plants or remote operations, where immediate on-site inspections may not always be feasible. By enabling condition-based maintenance, sensor monitoring helps optimize maintenance schedules, reduce unexpected downtime, and lower maintenance costs, all while ensuring machines operate safely and efficiently.

🛠 Tool Life Analytics

Effective tool management is crucial to maintaining high-quality production and minimizing waste. Tool Life Analytics provides continuous monitoring of tool usage, wear patterns, and performance degradation by collecting data from machine sensors and production logs. This system tracks the exact number of cycles, cutting time, or operational hours each tool has undergone and compares it against predefined thresholds to predict when a tool is nearing the end of its life.

Getting timely notifications before tools wear out helps avoid the risk of producing defective parts caused by dull or damaged tooling. Instead of relying on fixed schedules or reactive maintenance, manufacturers can shift to a condition-based maintenance model, optimizing tool replacement intervals and reducing unnecessary downtime. Additionally, by correlating tool condition data with scrap rates and quality issues, the analytics enable continuous process improvement and cost reduction. This proactive management of tooling assets not only improves product consistency but also extends tool life, reduces operational costs, and supports a leaner manufacturing process.

👥 Dynamic Workload Balancing

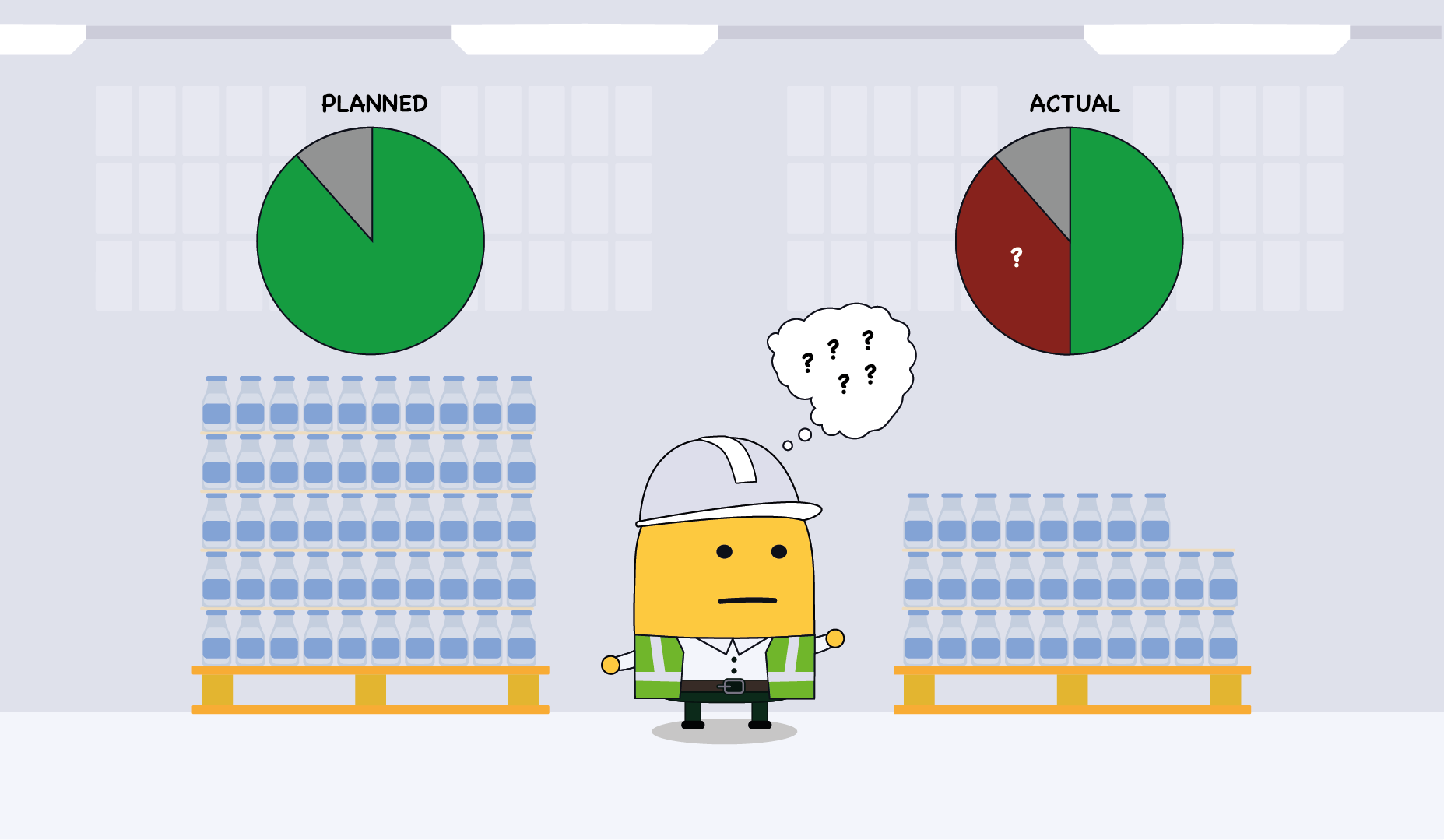

Efficient production depends not only on machines but also on how tasks are allocated among operators and equipment. Dynamic workload balancing continuously monitors operator availability, machine capacity, and real-time production demands to intelligently distribute tasks. This ensures that no individual or machine is overburdened while others remain underutilized. By adjusting workloads on the fly, manufacturers can maintain smooth workflows, reduce bottlenecks, and improve overall productivity.

This approach also helps accommodate unexpected changes such as absenteeism, machine downtime, or urgent orders by reallocating resources instantly to meet production targets. With real-time visibility into workforce and machine performance, managers can optimize shift planning, improve operator engagement, and enhance job satisfaction by creating a fair and balanced work environment. Ultimately, dynamic workload balancing drives better efficiency and responsiveness on the shop floor, supporting continuous operational excellence.

📈 Workforce Performance Dashboards

Workforce performance dashboards provide a comprehensive, real-time overview of operator efficiency, idle time, and task completion rates. By visualizing these key metrics in an intuitive format, supervisors can quickly identify high performers, detect bottlenecks, and uncover areas where additional training or support may be needed. These dashboards aggregate data from multiple sources—including machine outputs, attendance logs, and manual inputs—to offer a holistic view of workforce productivity.

With this insight, managers can make informed decisions to optimize shift assignments, balance workloads, and streamline operations. Tracking idle time helps highlight underutilized resources, while monitoring completion rates ensures production goals are consistently met. Ultimately, workforce performance dashboards empower manufacturers to improve operational efficiency, enhance employee accountability, and foster a culture of continuous improvement on the shop floor.