In today’s manufacturing world, the pressure to reduce operational costs while meeting sustainability goals is higher than ever. Customers, regulatory bodies, and global markets demand cleaner, more responsible production without sacrificing efficiency. To meet these demands, manufacturers need to move beyond traditional practices and embrace smart technologies that provide better visibility, control, and adaptability. This is where IIOT (Industrial Internet of Things) Technologies play a transformative role.

IIOT enables factories to continuously collect and analyze data from machines, energy systems, and environmental sensors. This data-driven insight allows manufacturers to identify energy-hungry processes, reduce carbon emissions, and minimize resource waste. Whether it’s optimizing HVAC systems, monitoring compressed air leaks, or reducing idle machine time, IIOT helps factories become greener without compromising performance. By embedding sustainability into operations, companies not only contribute to a healthier planet but also gain reputational and financial benefits.

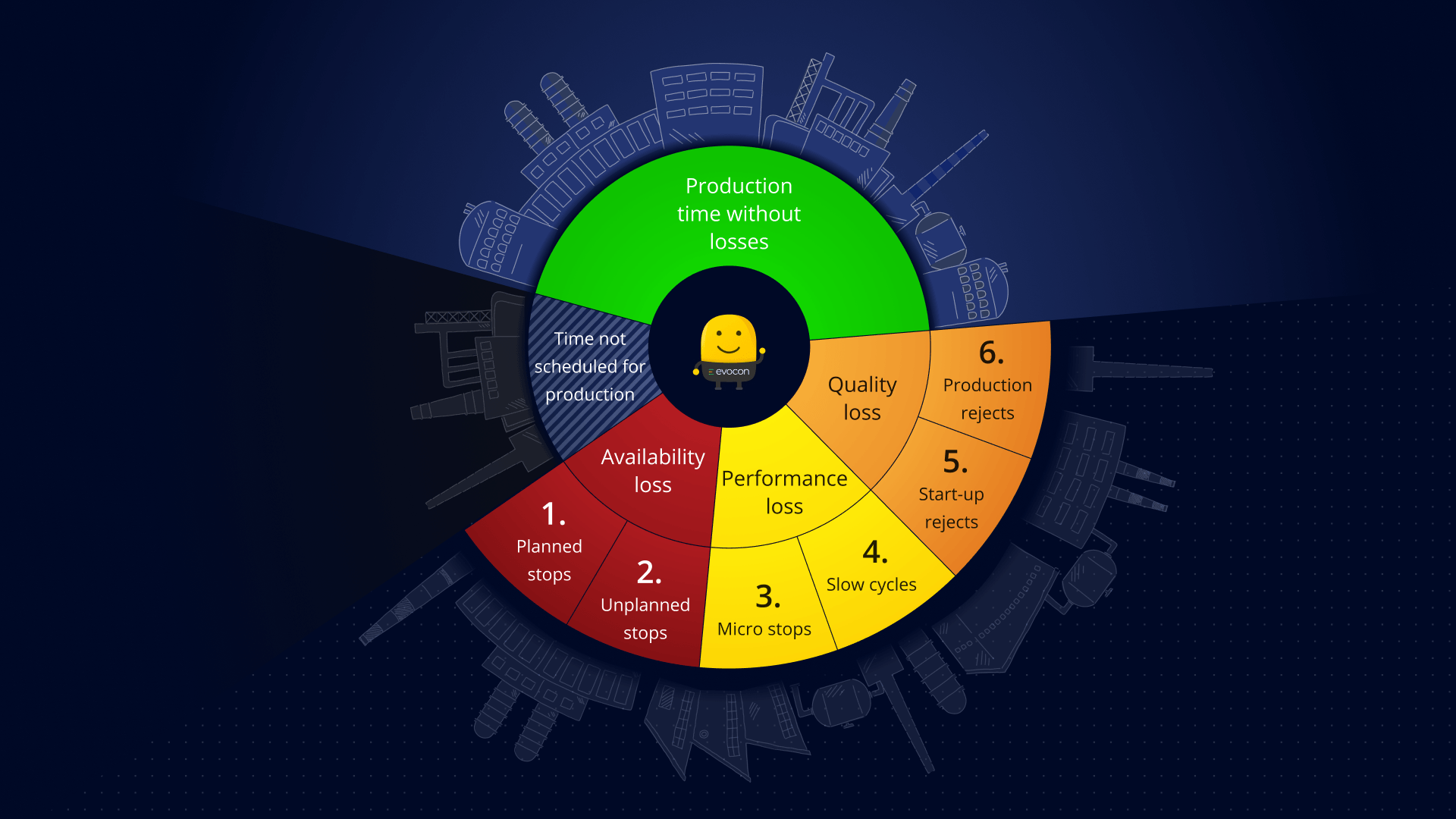

One of the most powerful advantages of IIOT is cost intelligence—the ability to track hidden inefficiencies and translate data into actionable savings. Real-time monitoring and predictive maintenance help reduce unplanned downtime and extend asset life, while smart scheduling and load balancing ensure optimal use of resources. This level of operational control allows manufacturers to make data-backed decisions that directly impact profitability. Over time, these incremental savings compound into significant financial improvements.

Beyond sustainability and cost control, IIOT lays the foundation for Industry 4.0 readiness. It enables the digital transformation of the factory floor, integrating machines, people, and systems into a unified, intelligent ecosystem. With IIOT, manufacturers are equipped to adapt quickly to market changes, customize production, and scale operations with precision. Investing in IIOT Technologies today is not just about solving current challenges—it’s about building a smart, connected, and resilient factory for the future.

Key Highlights:

💡 Work Order-Level Energy & Cost Tracking

Gain granular visibility into the energy consumption and associated costs for each product, work order, or production shift. By correlating energy usage directly with specific manufacturing activities, this feature helps uncover inefficiencies hidden at the order level—such as machines consuming excessive power during idle states or shifts with disproportionate energy-to-output ratios.

With this insight, manufacturers can better allocate costs, improve pricing accuracy, and drive sustainable practices by identifying energy-intensive processes. It also empowers teams to make smarter decisions about scheduling, equipment usage, and resource optimization—ultimately lowering overheads and boosting profitability per order.

♻️ Scrap Rate & Carbon Footprint Dashboards

Monitor material waste and emissions in real time to support sustainability initiatives and reduce production inefficiencies. By tracking scrap rates at each stage of the process, manufacturers can pinpoint where defects or overuse of raw materials are occurring—helping to minimize waste and improve yield.

These dashboards also provide visibility into carbon footprint per batch, shift, or product line, enabling data-driven decisions for greener operations. Aligning production metrics with environmental goals not only supports compliance and corporate responsibility but also enhances operational efficiency and long-term cost savings.

📢 Event-Based Alerts

Stay ahead of potential issues with real-time alerts that automatically flag abnormal spikes in energy consumption, production downtime, or unexpected emissions. These intelligent alerts help operations teams respond immediately to anomalies, reducing the risk of prolonged losses or safety incidents.

By customizing alert thresholds based on historical trends and operational benchmarks, manufacturers can ensure that critical deviations are never missed. Whether it’s an overheating motor, sudden drop in production rate, or an unexpected rise in carbon output, event-based alerts act as your 24/7 digital watchdog—ensuring faster responses, minimized waste, and optimized efficiency.

🧩 ERP, SAP & PLC Integration

Seamlessly connect your shop floor with enterprise systems like ERP, SAP, and PLCs to create a unified data ecosystem. This integration ensures that production data, inventory levels, machine statuses, and work orders flow in real time between operations and business platforms, eliminating manual data entry and reducing the risk of errors.

With synchronized systems, teams can make informed decisions faster—from scheduling and procurement to quality control and financial forecasting. Whether it's tracking raw material usage or aligning production plans with demand forecasts, integrated systems empower end-to-end visibility, process automation, and improved operational agility across the manufacturing lifecycle.

📂 Raw Data Export for RCA & Compliance

Gain full transparency and traceability by exporting detailed machine logs, production metrics, and event histories for in-depth root cause analysis (RCA) and regulatory audits. Whether you're investigating downtime causes or process deviations, raw data exports enable your team to drill down and uncover hidden inefficiencies.

Additionally, this data plays a critical role in meeting compliance and sustainability goals. Use it for generating accurate ESG reports, fulfilling ISO or industry-specific audit requirements, and supporting internal improvement initiatives with hard data. Reliable exports ensure you're always audit-ready and empowered to act with confidence.