Shopping cart

Your cart empty!

Stay connected with friends, family, and colleagues anywhere in the world.

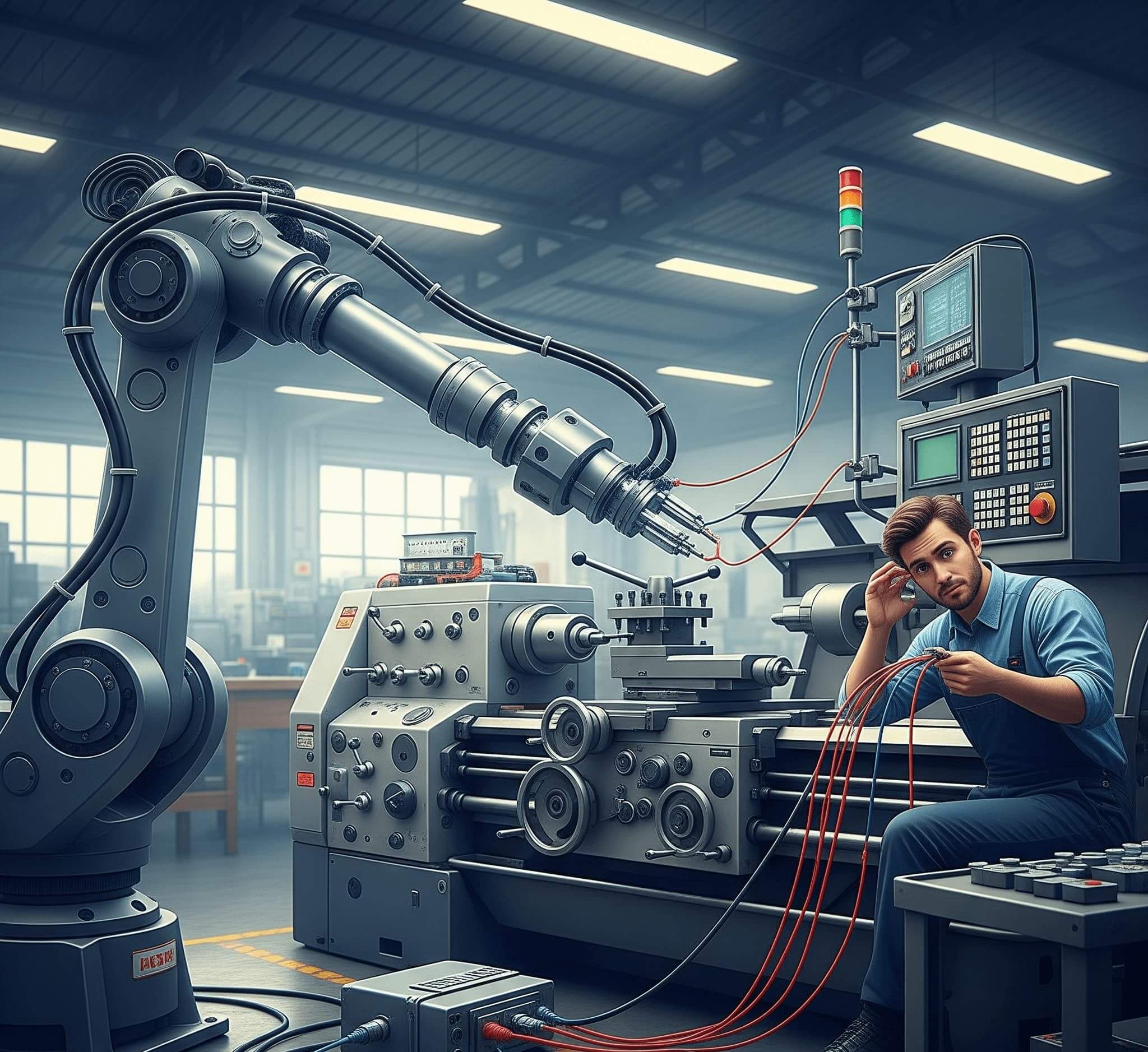

Monitor machines in real-time to optimize performance, enhance OEE and minimize downtime for valuable assets.

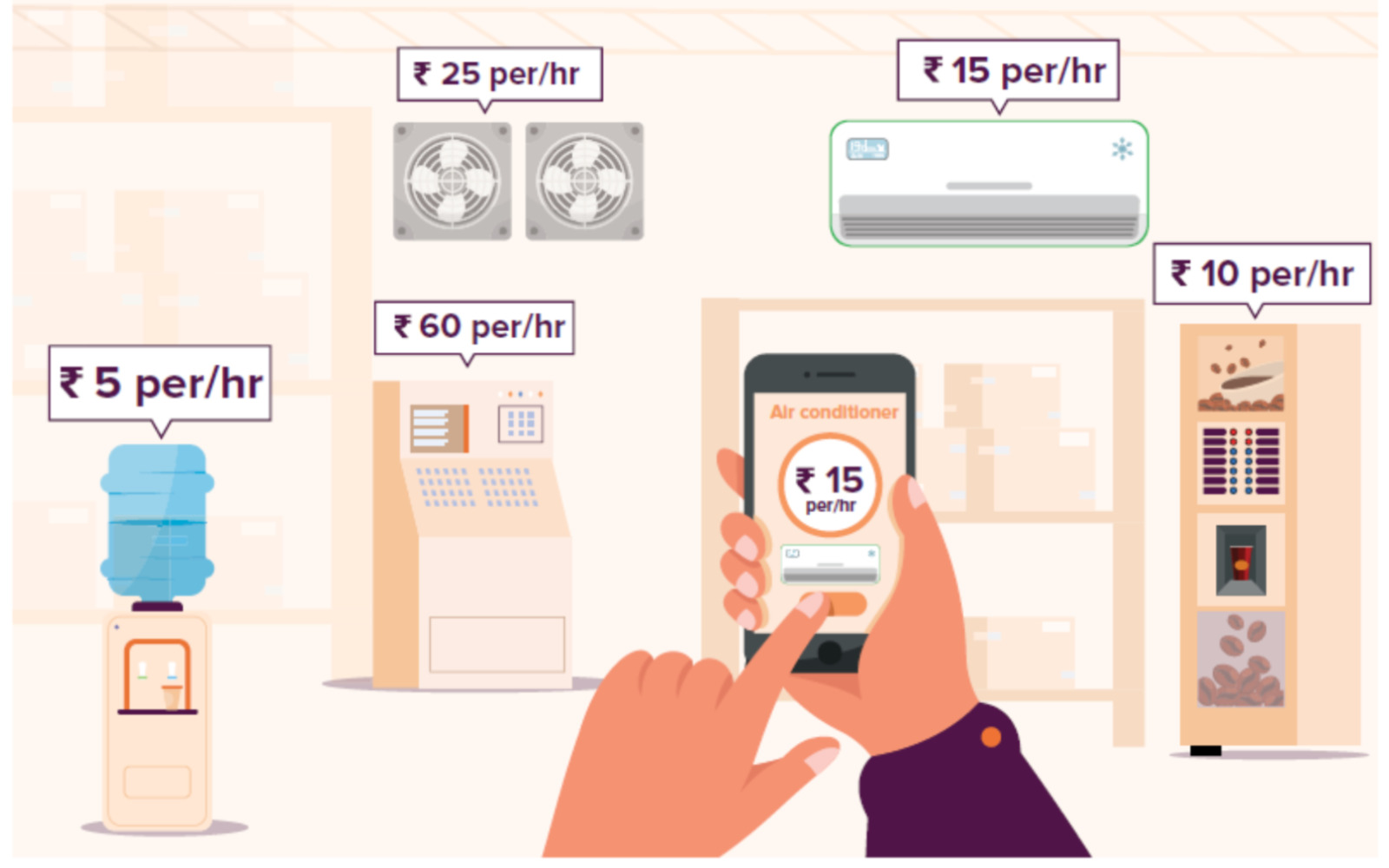

Plan and manage your energy consumption patterns, taking full control of your energy data to enable efficiency.

Leverage AI to simplify tasks, automate processes, and boost efficiency with real-time insights and smart predictions.

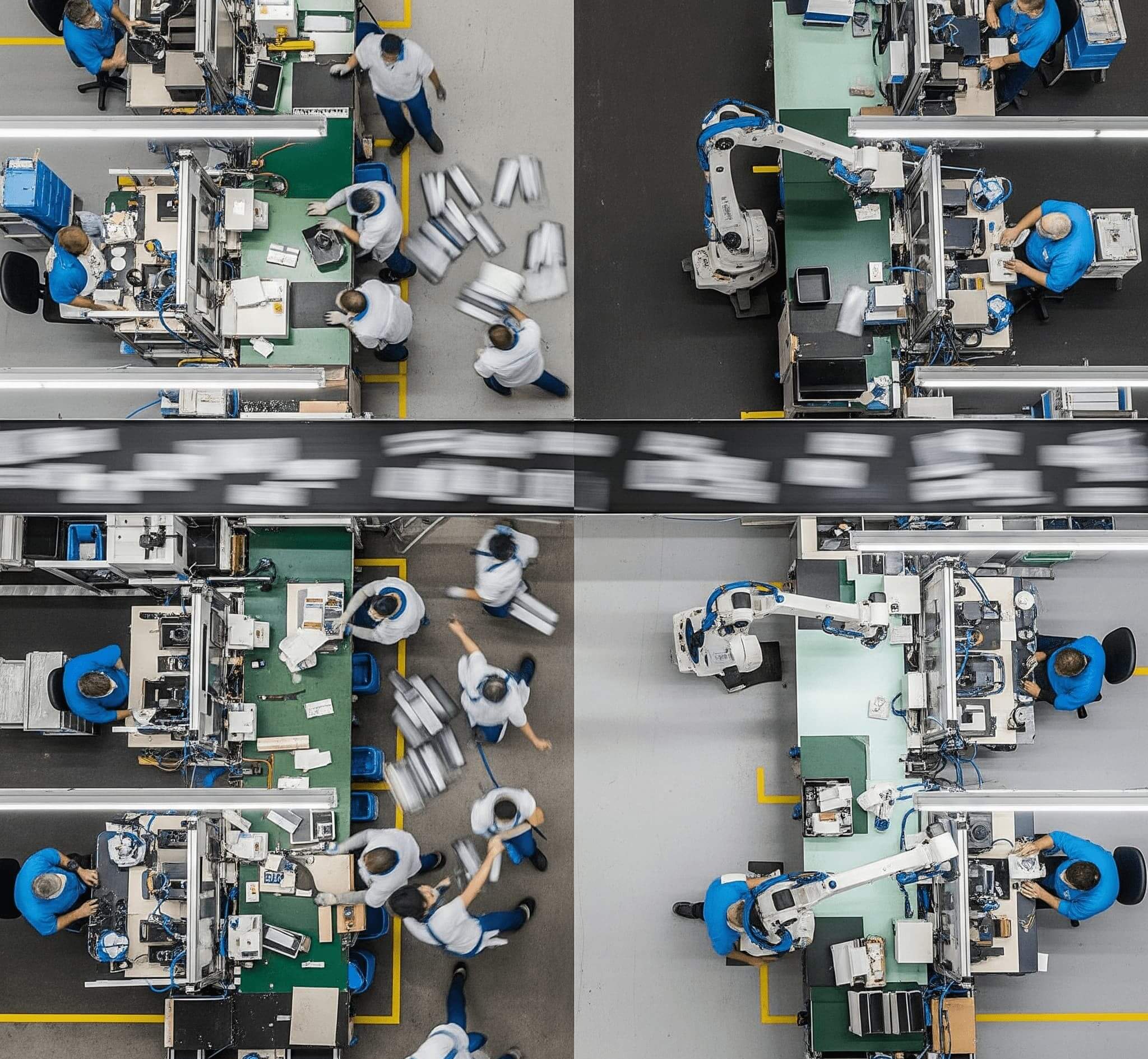

Problem: Frequent, unpredictable machine stoppages lead to production losses, missed deadlines, and high maintenance costs.

Our Solution:

• Real-time Downtime Monitoring with root cause categorization.

• Downtime Pareto Analysis with integrated maintenance codes.

• MTBF & MTTR tracking for reliability insights.

✅ Result: Reduced unplanned downtime and optimized maintenance schedules.

Problem: Plants struggle with low utilization rates and can't pinpoint whether performance issues stem from availability, performance, or quality.

Our Solution:

• Real-time OEE Monitoring with drill-downs.

• Cycle Time Variance Analysis to detect bottlenecks.

• Workforce Efficiency Tracking to improve human performance.

✅ Result: Better resource utilization and higher throughput.

Problem: Quality issues lead to customer dissatisfaction, rework, and scrap generation.

Our Solution:

• Rejection & Rework Analysis by product, machine, and shift.

• PPM (Parts Per Million) Reporting and cost of quality.

• QA-QC Integration for in-line and final inspection tracking.

✅ Result: Reduced quality failures and increased customer trust.

Problem: Relying on logbooks and Excel leads to inaccuracies and delayed decisions.

Our Solution:

• Automated Production Counters with good/bad part tracking.

• Interactive Dashboards for real-time visualization.

• Production History Reports for audit, analysis, and compliance.

✅ Result: Digitized shop floor with real-time control.

Problem: No visibility into how raw materials, machines, and human inputs impact the final output.

Our Solution:

• End-to-End Traceability from raw materials to delivery.

• Sensor Integration (temperature, pressure, tonnage, etc.) for granular control.

• Audit Trails for all quality and production events.

✅ Result: Full process transparency for audits and root cause analysis.

Problem: Machines consuming excess energy go unnoticed, leading to high operational costs.

Our Solution:

• Energy Monitoring Dashboards per machine/shift/product.

• Carbon Footprint Tracking for environmental compliance.

• Anomaly Alerts for spikes in usage.

✅ Result: Reduced energy bills and improved sustainability.

Problem: Some operators and machines are overloaded while others stay idle.

Our Solution:

• Dynamic Workload Balancing based on real-time data.

• Line Balancing Metrics to improve flow.

• Operator Efficiency Reports to manage teams better.

✅ Result: Streamlined operations and reduced inefficiencies.

Problem: Difficulty in connecting machines, ERP, and legacy systems.

Our Solution:

• ERP & SAP Compatibility (push & pull APIs).

• Universal PLC Support for easy integration.

• Modular Architecture for scalable, custom deployments.

✅ Result: Seamless digital transformation without infrastructure overhaul.

IIoT Technologies is built to eliminate guesswork, reduce waste, and unlock operational excellence. Whether you're a small unit or a multi-plant enterprise, we tailor solutions to your needs.

Book a free consultation 👉

“We are based in Europe and the latest Data Protection Regulation forces us to look for service suppliers than comply with this regulation and as we look to create our website and this builder just outstanding!”

*Yearly discount available on select plans.

Track of leads

Satisfied users

Team collaborations

The equipment downtime is usually reduced with the help of predictive analysis. It helps the industrialists to anticipate the accurate asset performance and health, thus scheduling on-time machine checks.

Factory downtime mainly occurs when the equipment starts performing low of their potential. It further affects the overall production as the maintenance and rectifying other issues takes time. This delays the production and hence affects the overall demand fulfillment.

IoT technology is well-equipped with advanced algorithms and analytics tools, which provide the managers with detailed insights regarding machine’s performance and its health. It helps identify the machine downtime accurately.

Broadly there are three types of machine downtimes: Shutdown or outage downtime, Schedule or planned downtime, Unscheduled or unplanned downtime.

Yes. Our system is built to retrofit with your current PLC-based machines and legacy infrastructure. Whether you have older equipment or a modern setup, we can connect and digitize it.

Simply reach out via our Schedule a Demo form. Our experts will assess your machines, communication systems, and factory layout to create a tailored implementation plan for your specific goals.

Our solution workswith a wide range of machines-CNCs,PLCs,injection molding,packaging,compressors,and more.If it runs in your factory, we can likely monitor it.

Absolutely. Our solution is fully customizable. We support multi-location, multi-factory environments and can tailor dashboards, alerts, KPIs, and workflows based on your industry or process needs.