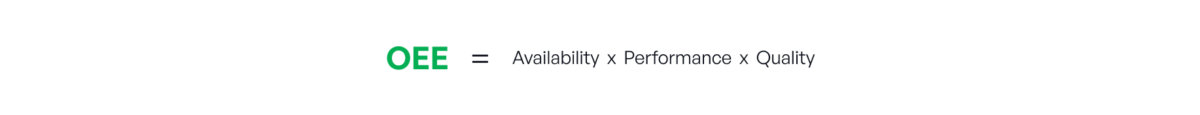

In the modern manufacturing industry, achieving maximum efficiency and productivity is crucial. Overall Equipment Effectiveness (OEE) is an essential metric that helps organizations understand and improve the performance of their production equipment. Simply put, OEE measures how effectively your manufacturing operations are utilized by analyzing three core components: Availability, Performance, and Quality.

In this guide, we will delve into the OEE formula and we’ll look at practical examples of OEE calculation, empowering you to identify areas for improvement and drive operational excellence.

How to Calculate OEE

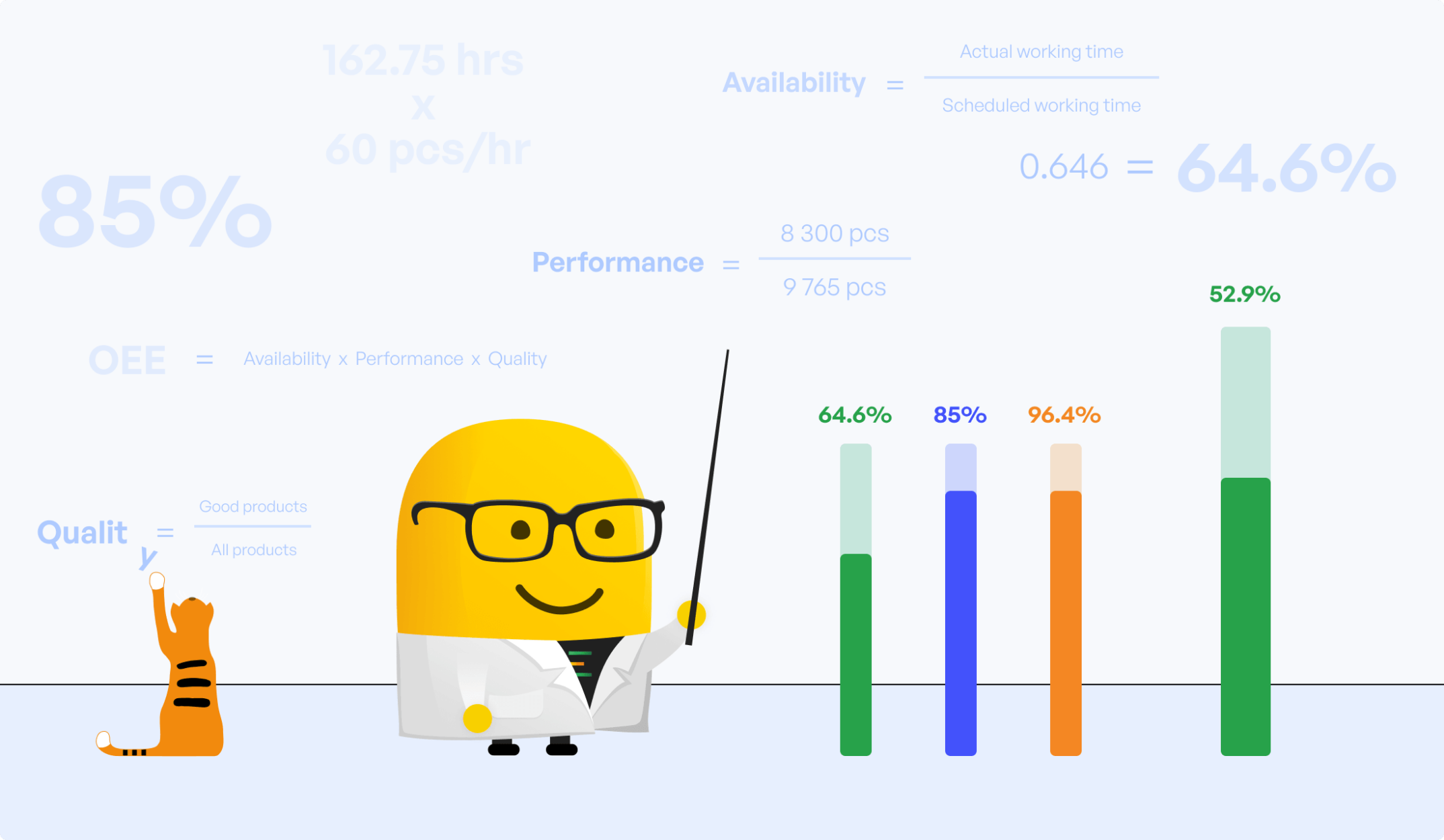

The most accurate OEE calculation is based on the three OEE factors: Availability, Performance, and Quality.

- Availability = Run Time / Planned Production Time

- Performance = (Ideal Cycle Time x Total Count) / Run Time

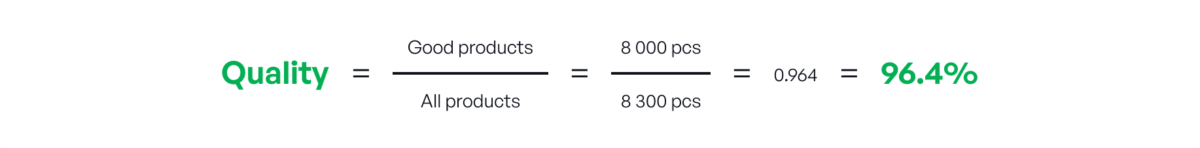

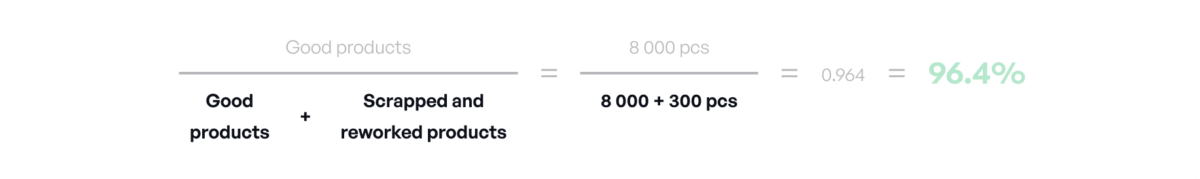

- Quality = Good Count / Total Count

- OEE = Availability x Performance x Quality

Here is the interactive visualization of the OEE formula:

OEE Calculation Example

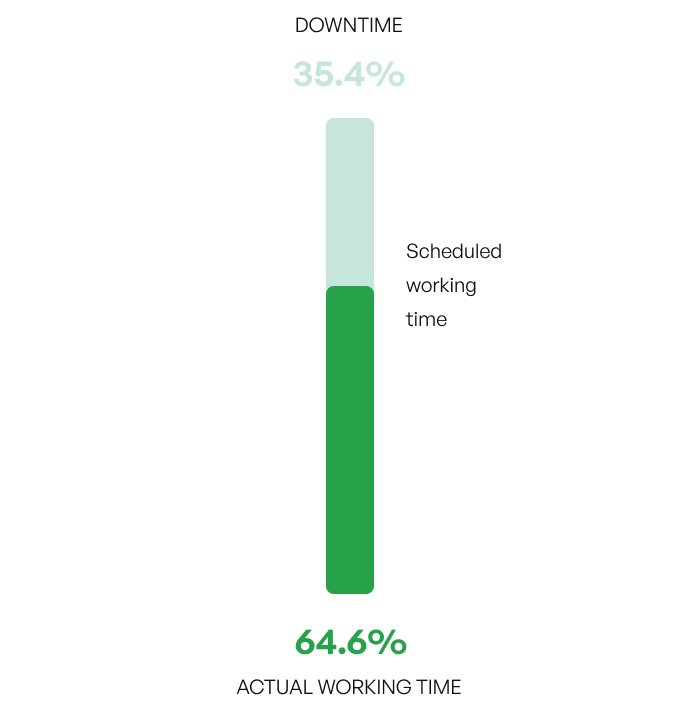

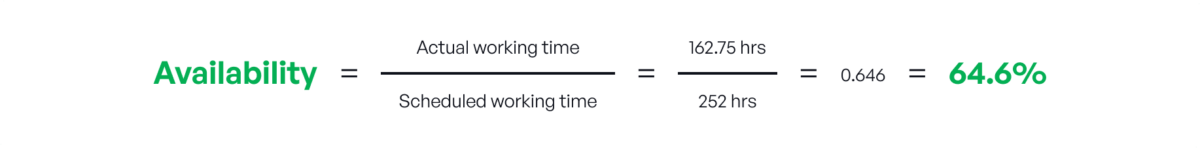

Availability

To find equipment/machine availability, divide the working time by the total scheduled time for that period. Then, multiply the result by 100 to show it as a percentage.

Doing that is simple. Register all stops (downtime) and subtract them from your scheduled working time.

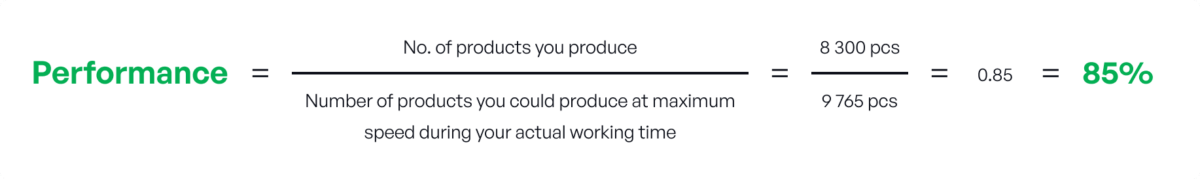

Performance

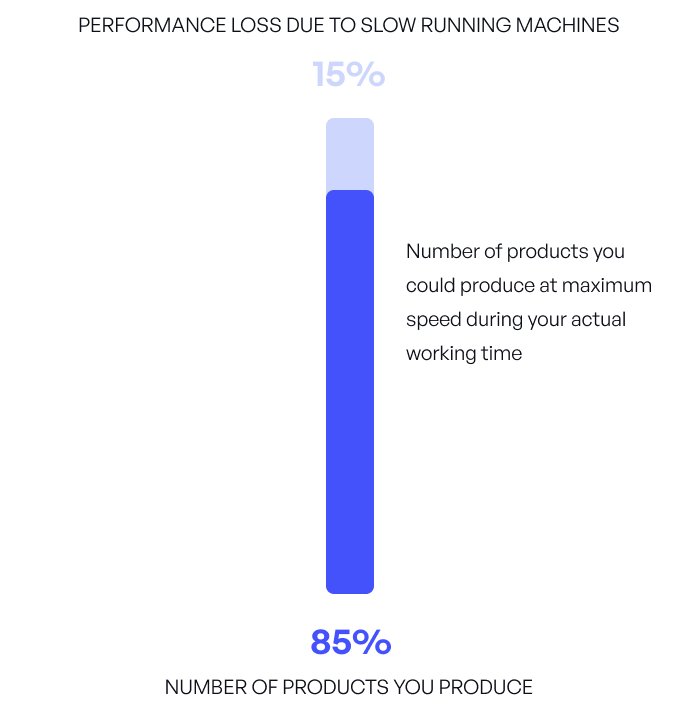

To calculate performance, you need to find out how many products you produce, and how it compares to the number of products that you could produce at maximum speed during your actual (not all scheduled, but actual) working time.

The formula of the Performance component of OEE is:

To do that, you simply multiply your actual working time and your maximum production speed.

How do you find out your maximum production speed?

Sometimes, the manufacturer of the machine specifies it (it might also be called “nameplate” or “ideal cycle time”). If not, you can identify the fastest recorded time. Firstly, look at the machines’ performance history. Next, calculate how many products you would make if your machine ran at that speed.

If you don’t have this data, we highly recommend implementing an OEE monitoring software that does these calculations for you and gives you the data you need to manage and improve OEE.

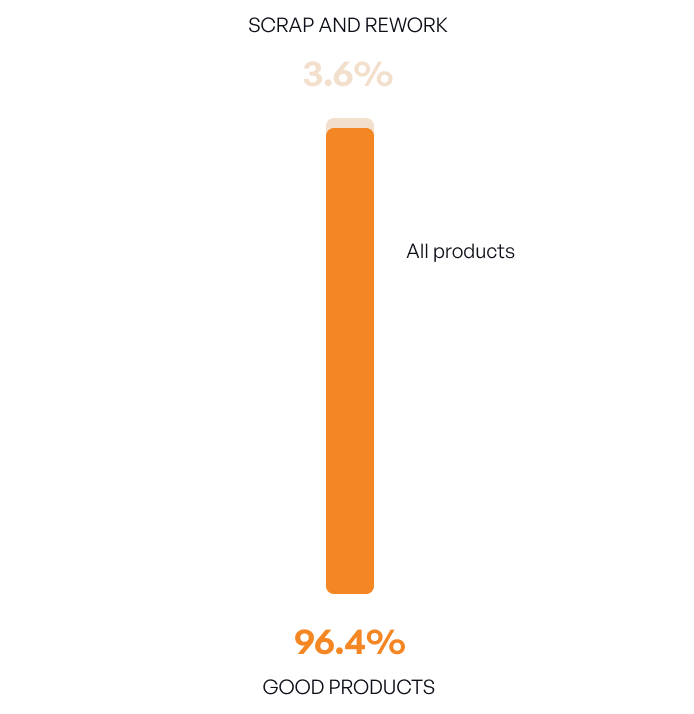

Quality

Simply put, quality shows the portion of good products among all products.

The formula for Quality is:

“All products” is simply good products + scrapped + reworkable products.

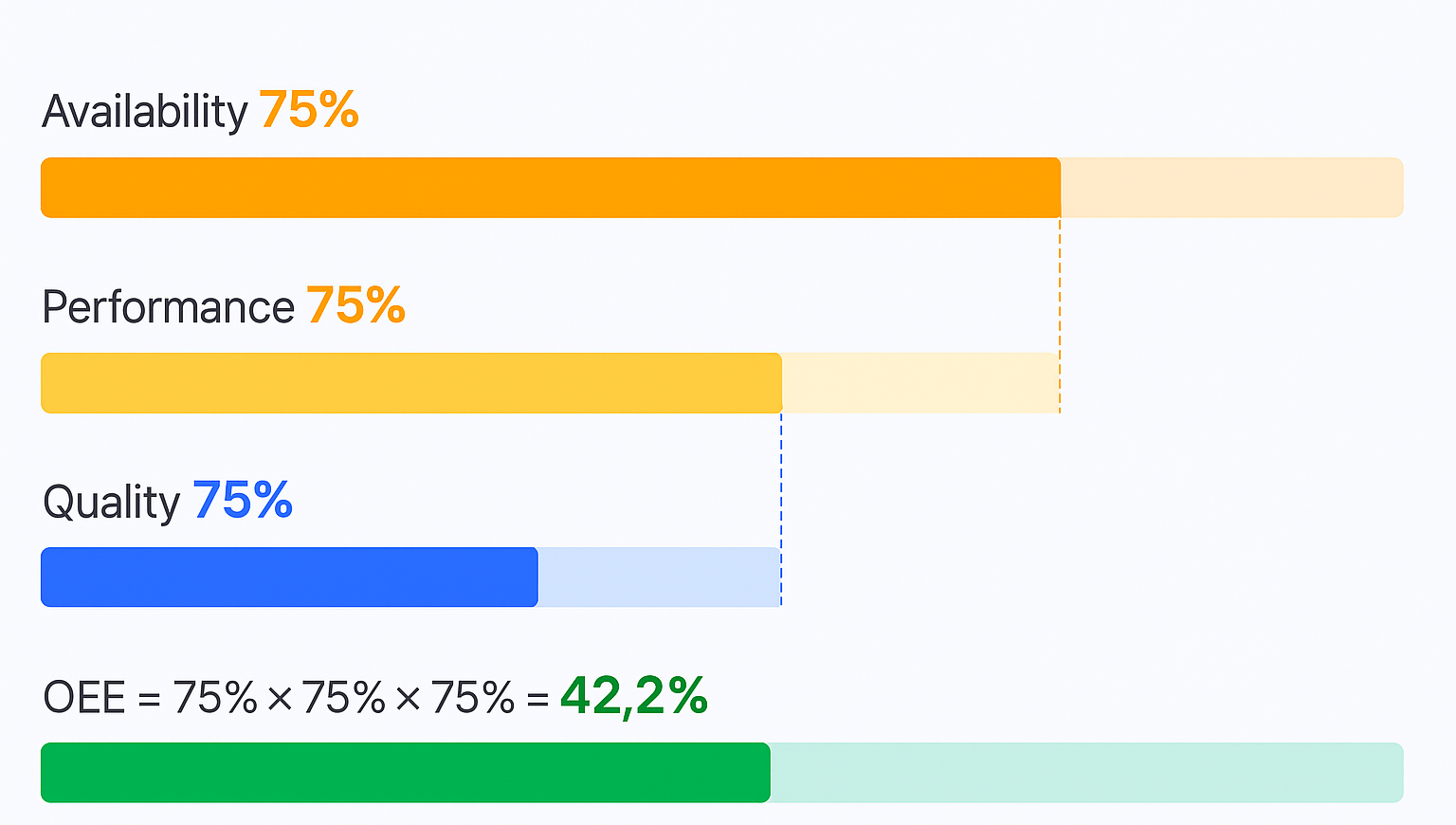

OEE Formula: Multiply the Three Components

If you multiply all OEE components, you will find the OEE value.

The best way to work this out is with our OEE calculator, but having the formula for OEE calculation is also incredibly useful. For example, if you know the other values, you could use them to discover a missing OEE component. If you know your OEE, performance, and quality, then you can find out availability like this: