Beyond just monitoring, IIOT Technologies enables proactive maintenance and smarter resource allocation by harnessing the power of predictive analytics. Real-time data streams from machines are analyzed to forecast potential failures or performance drops, allowing maintenance teams to intervene before costly breakdowns occur. This shift from reactive to predictive maintenance minimizes downtime, extends equipment lifespan, and significantly cuts repair costs. Additionally, by having a clear overview of machine status and workflow in real time, manufacturers can better balance workloads, optimize shift planning, and improve operator efficiency. This holistic approach ensures that every component of the manufacturing process is working in harmony, driving operational excellence and boosting overall throughput.

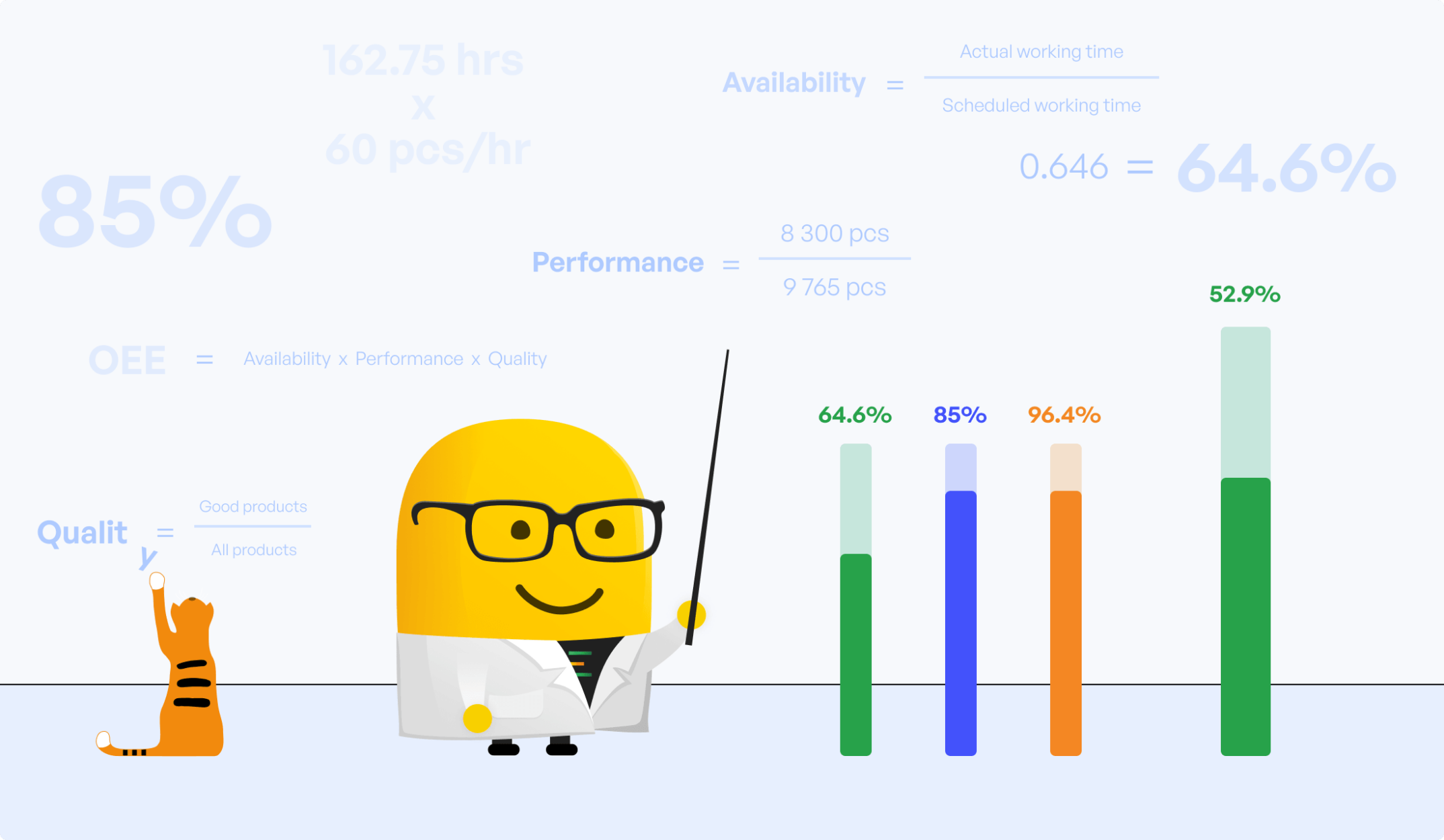

Furthermore, the integration of IIOT smart dashboards facilitates seamless communication across departments and with stakeholders. Data visualization tools transform complex datasets into intuitive charts and reports, making it easier for managers, engineers, and even executives to understand production trends and key performance indicators (KPIs) at a glance. This transparency fosters collaboration and aligns teams toward common goals, from quality control to sustainability initiatives. Moreover, IIOT Technologies can be customized to fit diverse manufacturing environments, from discrete parts assembly to continuous process industries, ensuring scalability and flexibility. As manufacturers continue to embrace digital transformation, the real-time insights provided by IIOT not only optimize current operations but also lay the groundwork for future innovations such as autonomous production lines and AI-driven decision-making.

In modern manufacturing, visibility is the first step toward efficiency. With IIOT Technologies, manufacturers can access real-time data across every machine and process, enabling faster decisions, early issue detection, and continuous improvement.

In addition to monitoring and predictive maintenance, IIOT Technologies plays a crucial role in enhancing overall product quality. By continuously tracking machine performance and production parameters in real time, manufacturers can quickly detect deviations that might affect quality standards. This immediate feedback loop allows operators to make swift adjustments, preventing defects before they occur and reducing costly rework or scrap. Moreover, comprehensive traceability features enable manufacturers to track every component and process step, facilitating faster root cause analysis during quality audits. This level of precision ensures that products consistently meet customer expectations and regulatory requirements, strengthening brand reputation and customer trust.

The deployment of IIOT solutions also leads to improved energy efficiency and sustainability on the factory floor. Real-time data on machine usage and energy consumption allows manufacturers to identify inefficiencies and waste, such as machines running idle or consuming excess power. With these insights, production managers can implement targeted energy-saving strategies that lower operational costs and reduce the environmental footprint of manufacturing operations. IIOT-driven sustainability not only helps companies meet increasingly stringent environmental regulations but also supports corporate social responsibility goals, making factories greener and more competitive in today’s eco-conscious market.

Key Highlights:

📊 Real-Time Dashboards

Real-Time Dashboards offer a centralized and dynamic view of your entire production landscape, allowing manufacturers to monitor key performance indicators (KPIs) at a glance. With IIOT Technologies, users can track critical metrics by product type, production category, or even customer segment — all in real time. This means you no longer have to sift through spreadsheets or wait for end-of-day reports to make decisions. Whether it's machine uptime, defect rates, output volumes, or operator performance, everything is visualized in one intuitive dashboard.

This immediate visibility not only accelerates response time to potential issues but also empowers teams to make data-driven improvements on the fly. By customizing views according to roles or departments, every stakeholder — from shop floor supervisors to senior executives — can access the insights they need to improve productivity, quality, and customer satisfaction. Ultimately, real-time dashboards act as a digital command center that drives operational agility, strategic planning, and continuous improvement across the entire manufacturing ecosystem.

✅ Live Production Counters

Live Production Counters provide real-time tracking of approved and rejected units as they move through the production line, offering manufacturers immediate visibility into output quality and quantity. This live data feed helps supervisors and quality control teams identify discrepancies, production slowdowns, or rising rejection rates the moment they occur. By monitoring these metrics in real time, manufacturers can intervene quickly to address issues before they escalate, reducing waste and downtime while maintaining production targets. The ability to visualize approved and rejected units on a digital interface keeps every stakeholder informed and accountable, enhancing operational efficiency and responsiveness.

Moreover, Live Production Counters go beyond just tallying numbers — they also capture and categorize rejection reasons. This feature enables detailed root cause analysis, allowing teams to pinpoint specific machines, materials, or processes responsible for defects. Over time, this data forms a valuable repository for trend analysis, helping manufacturers implement corrective actions, retrain staff, or adjust machine settings to prevent repeat issues. With this level of granularity, decision-makers can foster a culture of continuous improvement, ensuring that quality standards are upheld and productivity remains on track.

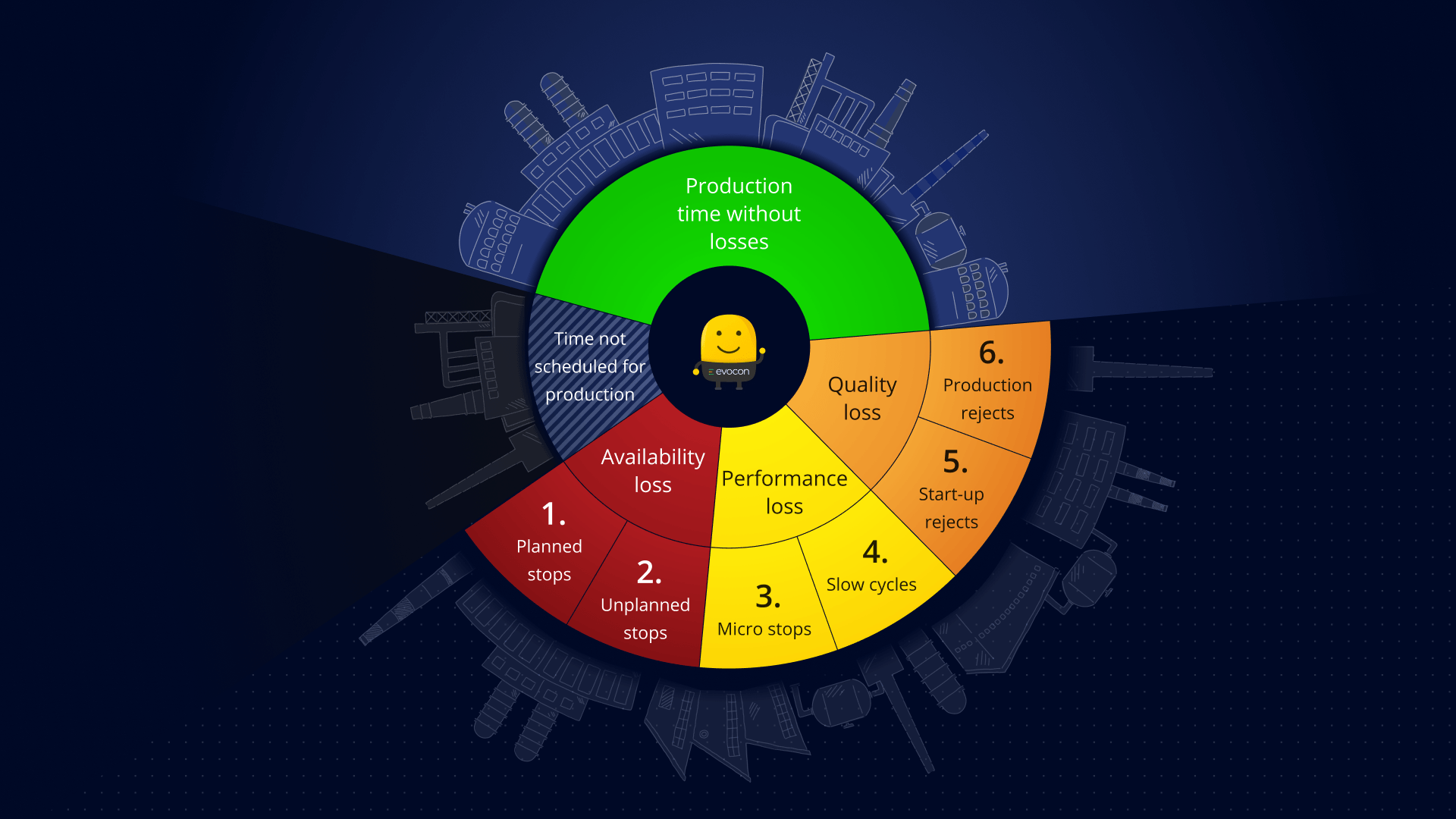

🕒 Cycle Time Variance Monitoring

Cycle Time Variance Monitoring is essential for identifying inefficiencies and maintaining consistent production flow. By continuously tracking the time each process or machine takes to complete a cycle, manufacturers can quickly detect deviations from standard benchmarks. These variances often signal underlying issues such as machine wear, operator delays, or process bottlenecks. With real-time alerts and visualizations, teams can take immediate corrective action to bring operations back within optimal timeframes. This not only helps in minimizing downtime and resource wastage but also ensures a more predictable and streamlined manufacturing process, ultimately improving throughput and product quality.

In addition to identifying immediate issues, Cycle Time Variance Monitoring provides valuable long-term insights into process stability and performance trends. By analyzing historical variance data, manufacturers can uncover recurring inefficiencies, assess the impact of equipment upgrades, and validate process improvements over time. This data-driven approach enables more accurate forecasting, better workforce planning, and optimized use of machinery.

🔔 Operator Alerts

Operator Alerts play a crucial role in maintaining smooth and efficient operations by instantly notifying shop floor teams of any process deviations, equipment anomalies, or safety concerns. These real-time alerts ensure that issues are addressed the moment they arise, minimizing downtime and preventing small problems from becoming major disruptions. Whether it’s a machine running outside its normal parameters or a sudden drop in production output, operators receive clear, actionable notifications that help them respond quickly.

Beyond immediate response, these alerts also promote a culture of accountability and awareness on the factory floor. By keeping everyone informed and aligned with operational standards, teams can work proactively to maintain quality, reduce errors, and enhance overall productivity. Operator Alerts can be customized based on roles or departments, ensuring that the right people get the right information at the right time—empowering a smarter, faster, and more connected workforce.

🧾 Full Process Traceability

Full Process Traceability allows manufacturers to follow every product’s journey from raw material intake to final dispatch, ensuring complete visibility and control at every stage. By capturing data at each step—such as material batch numbers, machine operations, inspection results, and operator details—companies can maintain a transparent and verifiable production record. This level of traceability is critical for quality assurance, helping quickly identify where and why defects occur, and enabling faster root cause analysis and corrective action.

Moreover, having detailed traceability strengthens compliance with industry standards and audit requirements. It builds customer trust by proving product authenticity and adherence to safety and quality norms. In the event of recalls or quality claims, manufacturers can act swiftly with pinpoint accuracy, reducing risks and protecting brand reputation. Full Process Traceability not only enhances operational accountability but also lays the groundwork for continuous process optimization.