Shopping cart

Your cart empty!

IIoT Technologies is a powerful and easy-to-use software that helps manufacturers to make smarter production decisions, reduce downtime, and boost efficiency in real time.

Get free trial

Tailored IIoT solutions designed to meet your unique business challenges and goals.

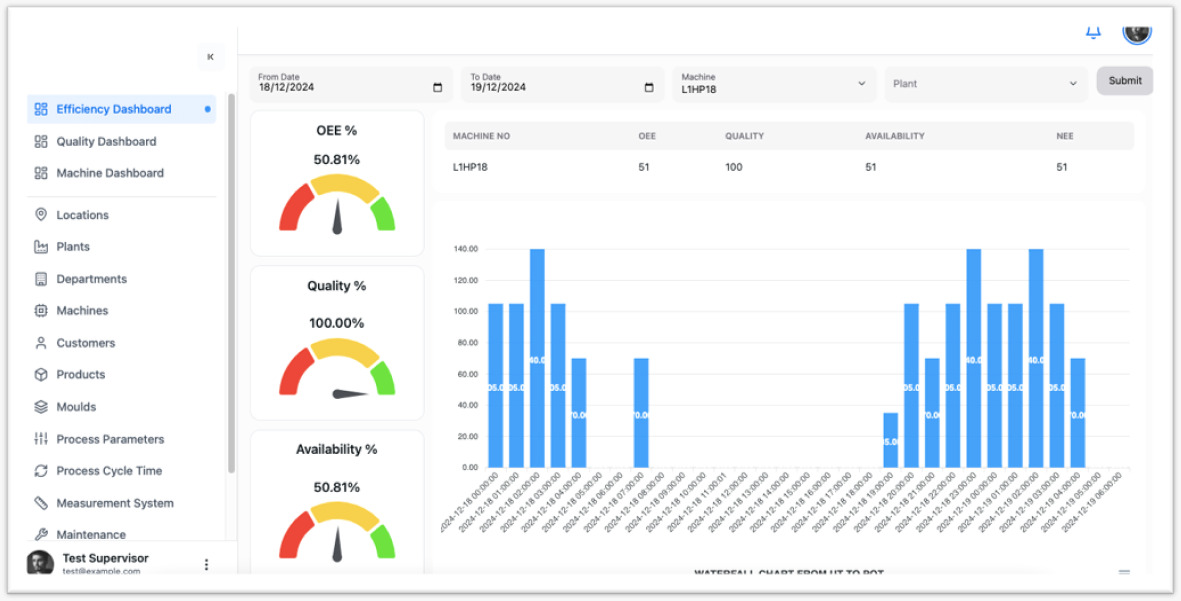

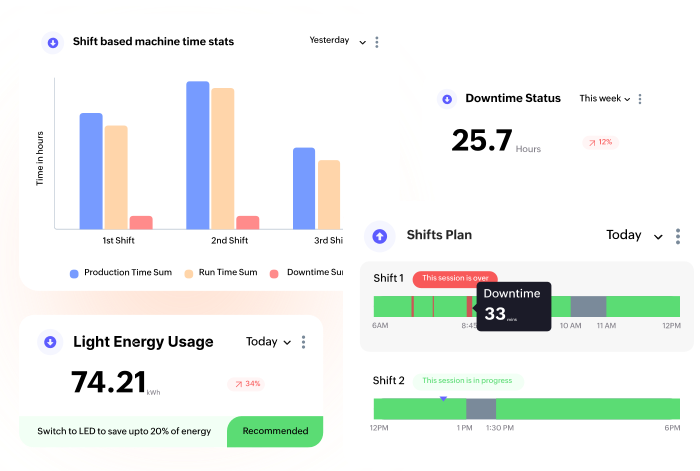

Monitor machines in real-time to optimize performance, enhance OEE and minimize downtime for valuable assets

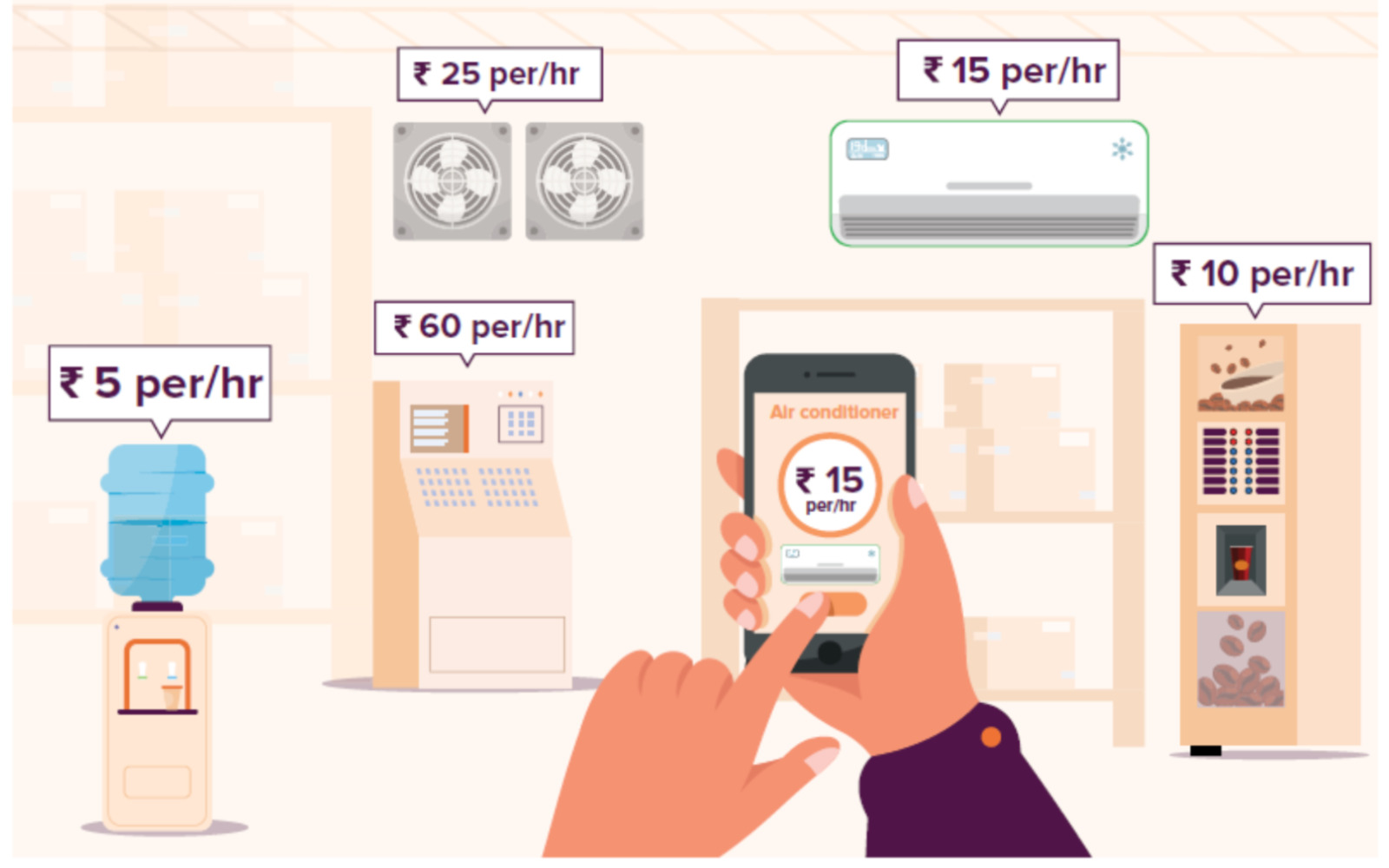

Plan and manage your energy consumption patterns, taking full control of your energy data to enable efficiency

Leverage AI to simplify tasks, automate processes, and boost efficiency with real-time insights and smart predictions

Improve your production by connecting our IIoT solution with your existing systems, reducing downtime and maximizing profits through seamless, real-time insights.

Monitor Live OEE, Operator performance, and Production status to keep your shop floor efficient. Make quicker decisions and minimize unplanned downtime.

Explore IIoT FeaturesIntegrate IIoT Technologies with your ERP, PLC, QA/QC, and MES systems to create a cloud-based,

connected, and smarter production environment.

Delivers a unified platform for innovation, automation, and

real-time operational control.

Collects data from any industrial equipment, regardless of protocol or vendor.

Adaptable architecture to fit varied industrial environments and use cases.

Delivers instant insights and anomaly detection for smarter decision-making.

Ensures encrypted data transfer and scalable cloud-based industrial operations.

Supports a wide range of IIoT use cases from manufacturing to energy and logistics.

Seamlessly connects with ERP, MES, SCADA, and other industrial systems.

The equipment downtime is usually reduced with the help of predictive analysis. It helps the industrialists to anticipate the accurate asset performance and health, thus scheduling on-time machine checks.

Factory downtime mainly occurs when the equipment starts performing low of their potential. It further affects the overall production as the maintenance and rectifying other issues takes time. This delays the production and hence affects the overall demand fulfillment.

IoT technology is well-equipped with advanced algorithms and analytics tools, which provide the managers with detailed insights regarding machine’s performance and its health. It helps identify the machine downtime accurately.

Broadly there are three types of machine downtimes: Shutdown or outage downtime, Schedule or planned downtime, Unscheduled or unplanned downtime.

Yes. Our system is built to retrofit with your current PLC-based machines and legacy infrastructure. Whether you have older equipment or a modern setup, we can connect and digitize it.

Simply reach out via our Schedule a Demo form. Our experts will assess your machines, communication systems, and factory layout to create a tailored implementation plan for your specific goals.

Our solution workswith a wide range of machines-CNCs,PLCs,injection molding,packaging,compressors,and more.If it runs in your factory, we can likely monitor it.

Absolutely. Our solution is fully customizable. We support multi-location, multi-factory environments and can tailor dashboards, alerts, KPIs, and workflows based on your industry or process needs.

“The IIoT software has completely transformed our shop floor operations. We now get real-time data from all machines, allowing us to reduce downtime and plan maintenance proactively. The dashboards are intuitive, and the team at IIoT Technologies provided excellent support during integration.”

“Implementing IIoT Technologies’ solution helped us increase overall equipment effectiveness (OEE) by 20%. The data accuracy and insights into machine performance are phenomenal.It's user-friendly and works seamlessly with our existing PLC systems. Highly recommended!”

“What impressed me most about IIoT Technologies was their ability to customize the software according to our unique workflow. The alerts for anomalies and energy usage tracking have improved our efficiency drastically. It’s been a game-changer for our digital transformation journey.”